Fillable Printable 26 8731C

Fillable Printable 26 8731C

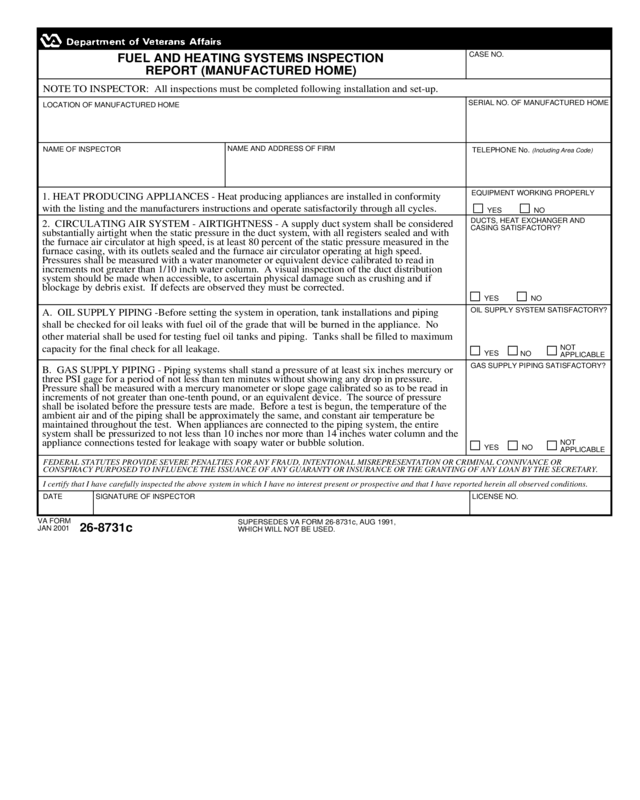

26 8731C

FUEL AND HEATING SYSTEMS INSPECTION

REPORT (MANUFACTURED HOME)

CASE NO.

NOTE TO INSPECTOR: All inspections must be completed following installation and set-up.

LOCATION OF MANUFACTURED HOME

SERIAL NO. OF MANUFACTURED HOME

NAME OF INSPECTOR

1. HEAT PRODUCING APPLIANCES - Heat producing appliances are installed in conformity

with the listing and the manufacturers instructions and operate satisfactorily through all cycles.

NAME AND ADDRESS OF FIRM

TELEPHONE No. (Including Area Code)

EQUIPMENT WORKING PROPERLY

YES

NO

B. GAS SUPPLY PIPING - Piping systems shall stand a pressure of at least six inches mercury or

three PSI gage for a period of not less than ten minutes without showing any drop in pressure.

Pressure shall be measured with a mercury manometer or slope gage calibrated so as to be read in

increments of not greater than one-tenth pound, or an equivalent device. The source of pressure

shall be isolated before the pressure tests are made. Before a test is begun, the temperature of the

ambient air and of the piping shall be approximately the same, and constant air temperature be

maintained throughout the test. When appliances are connected to the piping system, the entire

system shall be pressurized to not less than 10 inches nor more than 14 inches water column and the

appliance connections tested for leakage with soapy water or bubble solution.

2. CIRCULATING AIR SYSTEM - AIRTIGHTNESS - A supply duct system shall be considered

substantially airtight when the static pressure in the duct system, with all registers sealed and with

the furnace air circulator at high speed, is at least 80 percent of the static pressure measured in the

furnace casing, with its outlets sealed and the furnace air circulator operating at high speed.

Pressures shall be measured with a water manometer or equivalent device calibrated to read in

increments not greater than 1/10 inch water column. A visual inspection of the duct distribution

system should be made when accessible, to ascertain physical damage such as crushing and if

blockage by debris exist. If defects are observed they must be corrected.

A. OIL SUPPLY PIPING -Before setting the system in operation, tank installations and piping

shall be checked for oil leaks with fuel oil of the grade that will be burned in the appliance. No

other material shall be used for testing fuel oil tanks and piping. Tanks shall be filled to maximum

capacity for the final check for all leakage.

FEDERAL STATUTES PROVIDE SEVERE PENALTIES FOR ANY FRAUD, INTENTIONAL MISREPRESENTATION OR CRIMINAL CONNIVANCE OR

CONSPIRACY PURPOSED TO INFLUENCE THE ISSUANCE OF ANY GUARANTY OR INSURANCE OR THE GRANTING OF ANY LOAN BY THE SECRETARY.

I certify that I have carefully inspected the above system in which I have no interest present or prospective and that I have reported herein all observed conditions.

DATE SIGNATURE OF INSPECTOR

LICENSE NO.

OIL SUPPLY SYSTEM SATISFACTORY?

GAS SUPPLY PIPING SATISFACTORY?

VA FORM

JAN 2001

DUCTS, HEAT EXCHANGER AND

CASING SATISFACTORY?

SUPERSEDES VA FORM 26-8731c, AUG 1991,

WHICH WILL NOT BE USED.

26-8731c

NOT

APPLICABLE

NOT

APPLICABLE

YES

NO

YES

NO

YES

NO