Fillable Printable Form F417-267-000

Fillable Printable Form F417-267-000

Form F417-267-000

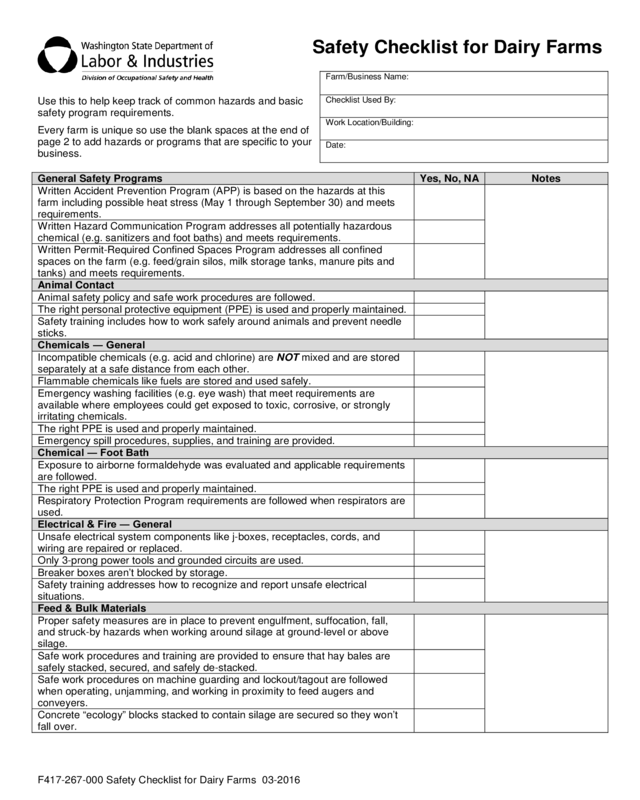

Safety Checklist f or Dair y Farms

Fa rm/Bus iness Name:

Use this to help keep track of common hazards and basic

safety program requirements.

Every farm is unique so use the blank spaces at the end of

page 2 to add hazards or programs that are specific to your

business.

Checklist Used By:

Work Location/Bui l di ng:

Date:

General Safety Programs

Yes, No, NA

Notes

Written Accident Prevention Program (APP) is based on the hazards at this

farm including possible heat stress (May 1 through September 30) and meets

requirements.

Written Hazard Communication Program addresses all potentially hazardous

chemical (e.g. sanitizers and foot baths) and meets requirements.

Written Permit-Required Confined Spaces Program addresses all confined

spaces on the farm (e.g. feed/grain silos, milk storage tanks, manure pits and

tanks) and meets requirements.

Animal Contact

Animal safety policy and safe work procedures are followed.

The right personal protective equipment (PPE) is used and properly maintained.

Safety training includes how to work safely around animals and prevent needle

sticks.

Chemicals ― General

Incompatible chemicals (e.g. acid and chlorine) are NOT mixed and are stored

separately at a safe distance from each other.

Flammable chemicals like fuels are stored and used safely.

Emergency washing facilities (e.g. eye wash) that meet requirements are

available where employees could get exposed to toxic, corrosive, or strongly

irritating chemicals.

The right PPE is used and proper ly maintain ed.

Emergency spill procedures, supplies, and training are provided.

Chemical ― Foot Bath

Exposure to airborne formaldehyde was evaluated and applicable requirements

are followed.

The right PPE is used and proper ly maintain ed.

Respiratory Protection Program requirements are followed when respirators are

used.

Electrical & Fire ― General

Unsafe electrical system components like j-boxes, receptacles, cords, and

wiring are repaired or replaced.

Onl y 3-prong power tools and grounded circuits are used.

Breaker boxes aren’t blocked by storage.

Safety training addresses how to recognize and report unsafe electrical

situations.

Feed & Bulk Materials

Proper safety measures are in place to prevent engulfment, suffocation, fall,

and struck-b y hazards whe n working around sil age at groun d-level or above

silage.

Safe work procedures and training are provided to ensure that hay bales are

safely stacked, secured, and safely de-stacked.

Safe work procedures on machine guarding and lockout/tagout are followed

when operati ng, unj am ming, and working in prox imity to feed augers and

conveyers.

Concrete “ecology” blocks stacked to contain silage are secured so they won’t

fall over.

F417-267-000 Safety Checklist for Dairy Farms 03-2016

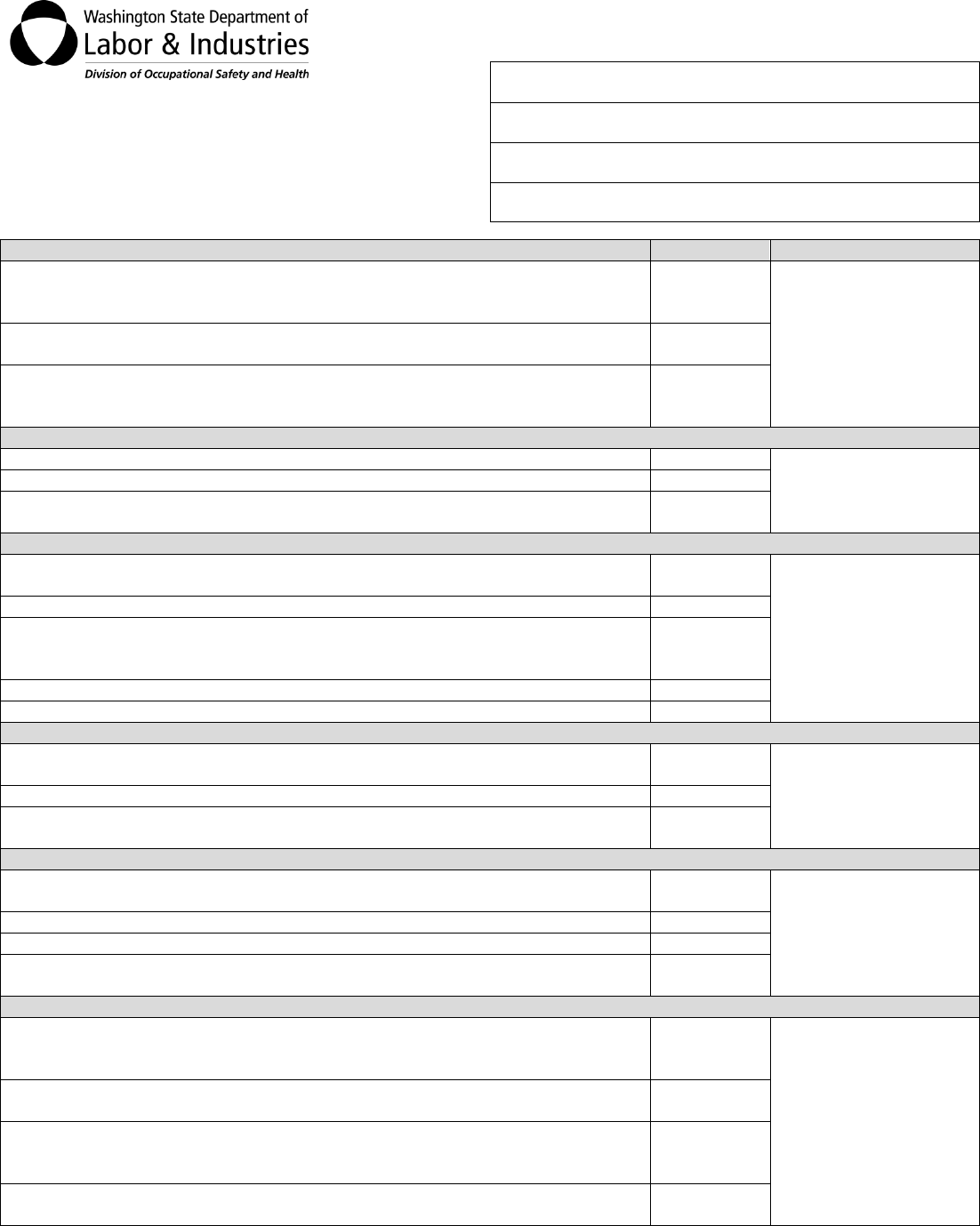

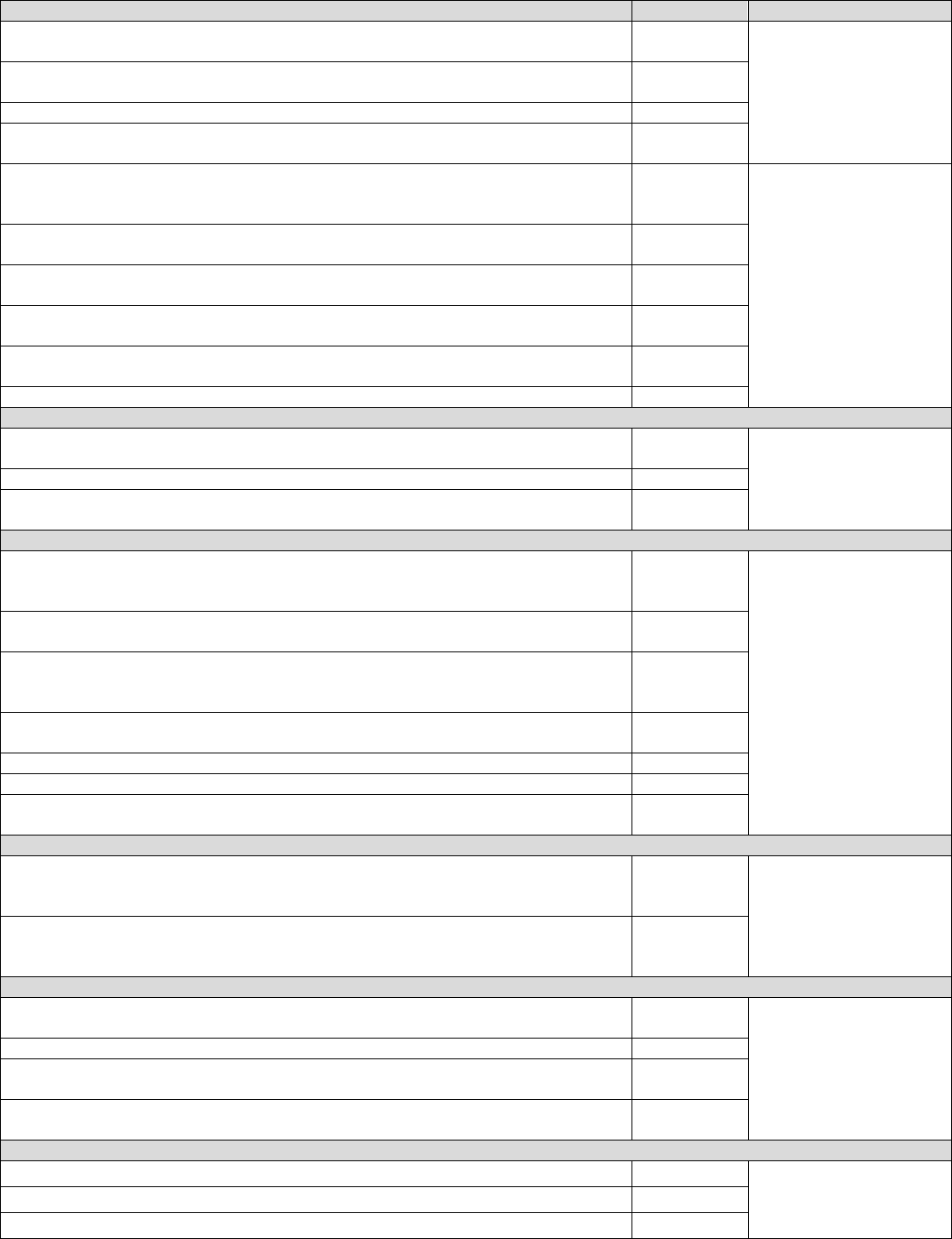

General Work Environment

Yes, No, NA

Notes

Standard guar dr ai ls are ins tal led wher e ver walking or working surf aces are

elevated more than 48 inches above any adjacent floor or ground.

Fall protection requirements are followed when employees work at or above 4

feet from an adjacent floor or ground level.

Unsafe walking, climbing, and working surfaces are repaired and replaced.

Working areas are clean and clear of clutter and debris that could create trip or

struck-by hazards.

The right PPE is used and properly maintained to protect against animal waste,

animal dander, and other materials that could cause infections, allergies, and

other illness es.

Safe work procedures, supplies, and training are provided for rodent clean-up

activities.

Compressed air used for cleaning is limited to 30 psi or less and PPE is

required to be used to protect from flying particles.

High noise areas (e.g. around feed mixer or hoof trimming areas) have been

identified and applicable hearing conservation requirements are followed.

Safety training includes how to minimize risk to back, neck, and other possible

strain or sprain injuries.

A first-aid kit and trained person is available at all times.

Ladders

Employees have been trained on how to correctly select, inspect, set-up, and

safely use ladders.

All damaged ladders are tagged and removed from use or replaced.

Metal ladders are prohibited where the ladder or person could come in contact

with energized parts (e.g. overhead electrical lines).

Machinery, Equipment, & Vehicles

Dangerous moving mechanical parts (e.g. rotating shafts like PTOs on tractors,

belts and pulleys, flywheels and gears, chains and sprockets, blades and shear

points) are safeguarded.

Mechanical parts are de-energized or disengaged and blocked or locked out to

prevent dangerous movement during maintenance and other activity.

Tractors, skid steers, portable augers, grain probes, ladders, poles, rods,

irrigation pipes cannot directly or indirectly make contact with energized

overhead or buried power lines.

Safety training includes safe operation of tractors, ATVs, manure scrapers,

augers, agitators, and other vehicles or equipment.

Requirements for using ROPS and seatbelts are followed.

Helmet s are worn duri ng A T V use.

All who operate farm vehicles (except agricultural tractors) on public roads have

a valid operator’s license.

Manure Storage

Manure pits, ponds, lagoons, and other manure storage areas are guarded (e.g.

railing, fence, or other barriers), warning signs are posted at access points, and

a means of rescue is provided when access is possible.

Safety training addresses where manure storage areas and boundaries are

located, the dangers (e.g. drowning, deadly or ignitable manure gases, and

mechanical hazards), and safety measures to follow.

Welding, Cutting, and Brazing

Precautions are taken to prevent air or oxygen from mixing with flammable

gases (except when using a burner or standard torch).

“DANGER , NO SMOKING” signs (or the equivalent) are posted.

The right PPE is used and properly maintained to protect from flash burns,

sparks, dust and debris, toxic fume and gases, and excess noise.

Respiratory Protection Program requirements are followed when respirators are

used.

Other Hazards ― add any hazards or safety program(s) not listed above.

F417-267-000 Safety Checklist for Dairy Farms 03-2016

RESET