Fillable Printable Operation And Maintenance Checklist

Fillable Printable Operation And Maintenance Checklist

Operation And Maintenance Checklist

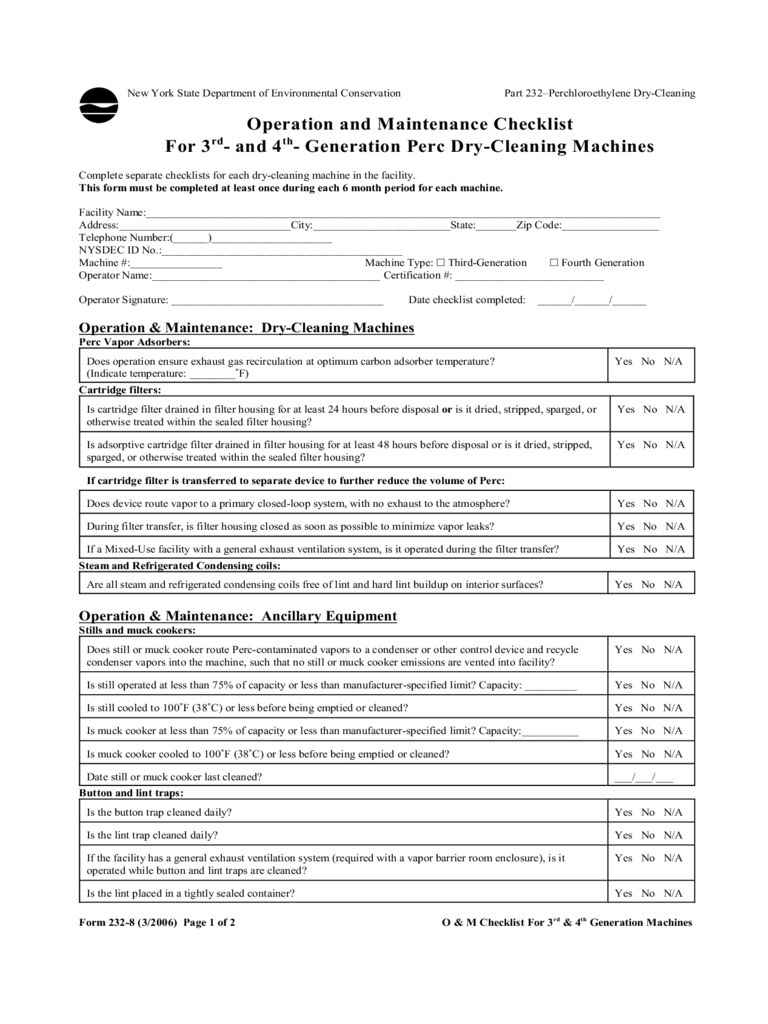

New York State Department of Environmental Conservation Part 232–Perchloroethylene Dry-Cleaning

Operation and Maintenance Checklist

For 3 - and 4 - Generation Perc Dry-Cleaning Machines

rd th

Complete separate checklists for each dry-cleaning machine in the facility.

This form must be completed at least once during each 6 month period for each machine.

Facility Name:__________________________________________________________________________________________

Address:______________________________City:________________________State:_______Zip Code:_________________

Telephone Number:(______)_____________________

NYSDEC ID No.:__________________________________________

Machine #:________________ Machine Type: ~ Third-Generation ~ Fourth Generation

Operator Name:________________________________________ Certification #: __________________________

Operator Signature: _____________________________________ Date checklist completed: ______/______/______

Operation & Maintenance: Dry-Cleaning Machines

Perc Vapor Adsorbers:

Does operation ensure exhaust gas recirculation at optimum carbon adsorber temperature?

(Indicate temperature: ________<F)

Yes No N/A

Cartridge filters:

Is cartridge filter drained in filter housing for at least 24 hours before disposal or is it dried, stripped, sparged, or

otherwise treated within the sealed filter housing?

Yes No N/A

Is adsorptive cartridge filter drained in filter housing for at least 48 hours before disposal or is it dried, stripped,

sparged, or otherwise treated within the sealed filter housing?

Yes No N/A

If cartridge filter is transferred to separate device to further reduce the volume of Perc:

Does device route vapor to a primary closed-loop system, with no exhaust to the atmosphere? Yes No N/A

During filter transfer, is filter housing closed as soon as possible to minimize vapor leaks? Yes No N/A

If a Mixed-Use facility with a general exhaust ventilation system, is it operated during the filter transfer? Yes No N/A

Steam and Refrigerated Condensing coils:

Are all steam and refrigerated condensing coils free of lint and hard lint buildup on interior surfaces? Yes No N/A

Operation & Maintenance: Ancillary Equipment

Stills and muck cookers:

Does still or muck cooker route Perc-contaminated vapors to a condenser or other control device and recycle

condenser vapors into the machine, such that no still or muck cooker emissions are vented into facility?

Yes No N/A

Is still operated at less than 75% of capacity or less than manufacturer-specified limit? Capacity: _________ Yes No N/A

Is still cooled to 100<F (38<C) or less before being emptied or cleaned? Yes No N/A

Is muck cooker at less than 75% of capacity or less than manufacturer-specified limit? Capacity:__________ Yes No N/A

Is muck cooker cooled to 100<F (38<C) or less before being emptied or cleaned? Yes No N/A

Date still or muck cooker last cleaned? ___/___/___

Button and lint traps:

Is the button trap cleaned daily? Yes No N/A

Is the lint trap cleaned daily? Yes No N/A

If the facility has a general exhaust ventilation system (required with a vapor barrier room enclosure), is it

operated while button and lint traps are cleaned?

Yes No N/A

Is the lint placed in a tightly sealed container? Yes No N/A

Form 232-8 (3/2006) Page 1 of 2 O & M Checklist For 3 & 4 Generation Machines

rd th

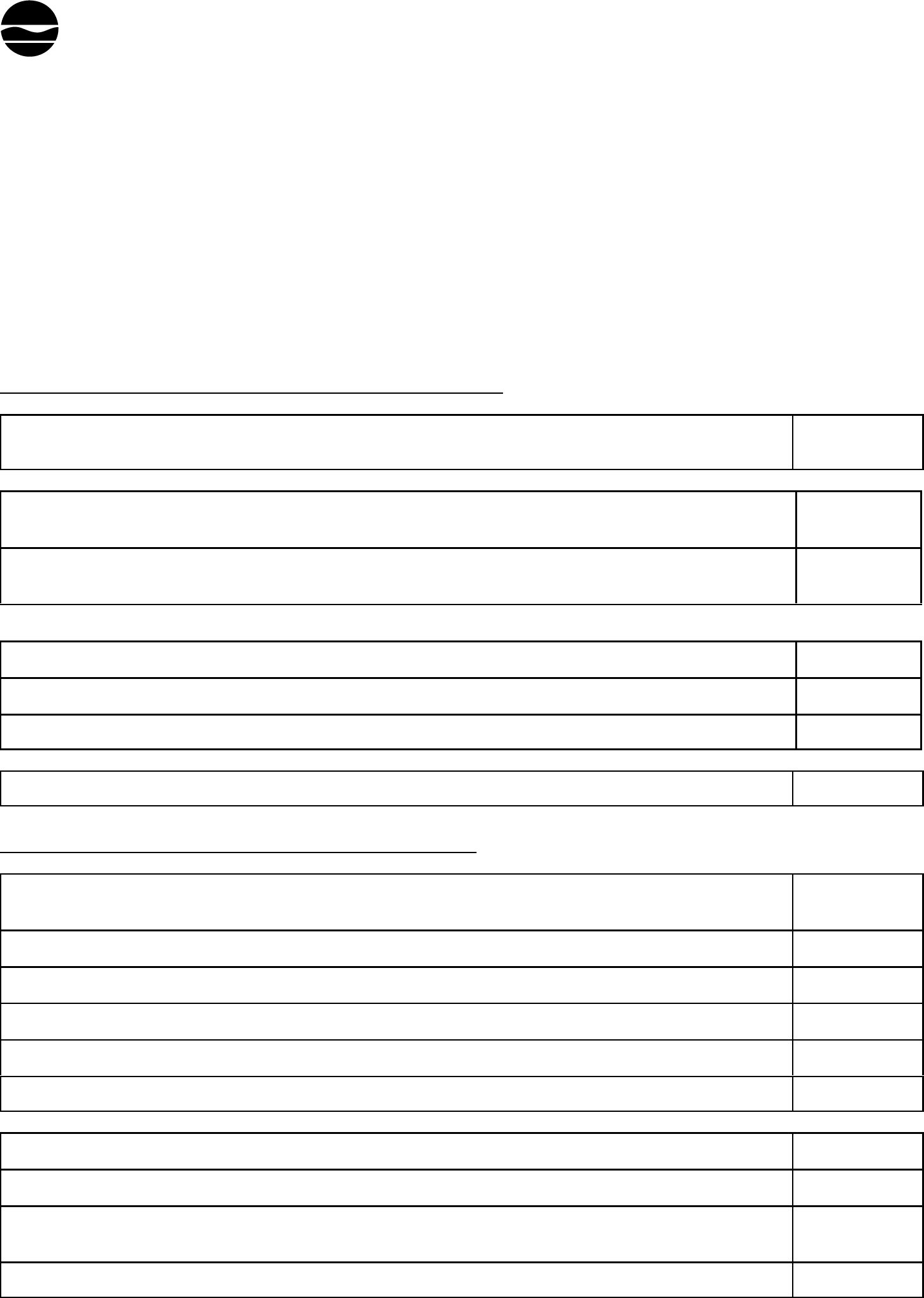

Operation & Maintenance: Ancillary Equipment, continued

Wastewater Treatment Units:

Is wastewater physically separated and treated with double-carbon filtration to 20 ppb or less Perc concentration

prior to proper disposal?

Yes No N/A

Are wastewater treatment unit carbon cartridges replaced according to the schedule specified by the manufacturer

to assure an effluent quality that does not exceed 20 ppb Perc?

Replacement schedule specified by manufacturer: ______________________________________________

Yes No N/A

If evaporators or “misters” are subsequently used to dispose of treated wastewater, are they operated to ensure

that no liquid Perc or visible emulsion is allowed to vaporize?

Yes No N/A

Dip tanks:

Are dip tanks maintained under negative pressure? Yes No N/A

Are vent emissions from dip tanks less than 20 ppm?

reading: ___________ ppm

Yes No N/A

Drying cabinets:

Are drying cabinets maintained under negative pressure? Yes No N/A

Are vent emissions from drying cabinets less than 20 ppm?

reading: ___________ ppm

Yes No N/A

Operation & Maintenance: Other

Are design specifications and operating manuals present and accessible on-site for each dry cleaning system and

each emission control device located at the dry cleaning facility?

Yes No N/A

Are all of the following equipment maintained as recommended by manufacturer’s specifications:

hose and pipe connections, fittings, couplings, and valves? Yes No N/A

door gaskets and seatings? Yes No N/A

filter gaskets and seatings? Yes No N/A

pumps? Yes No N/A

water separators? Yes No N/A

muck cookers? Yes No N/A

stills? Yes No N/A

exhaust dampers? Yes No N/A

diverter valves? Yes No N/A

cartridge filter housings? Yes No N/A

drying sensors? Yes No N/A

Are all parts of the dry cleaning system where Perc may be emitted to the atmosphere, include solvent containers,

kept closed at all times except when access is required for proper operation and maintenance?

Yes No N/A

Is the dry-cleaning system operated to ensure Perc releases are contained and do not migrate to sewer systems or

groundwater?

Yes No N/A

Is any equipment operated 15 days after a leak is detected and repair is not yet complete?

If yes, did facility obtain a leak-repair extension from the Department for this operation?

Date of leak-repair extension: ____/____/____

Yes No N/A

Yes No N/A

Failure to complete this form is a violation of 6NYCRR Part 232 and could result in enforcement action,

including monetary penalties.

This form must be kept on-site for at least five (5) years.

Form 232-8 (3/2006) Page 2 of 2 O & M Checklist For 3 & 4 Generation Machines

rd th