Fillable Printable Root Cause Analysis For Beginners

Fillable Printable Root Cause Analysis For Beginners

Root Cause Analysis For Beginners

QUALITY PROGRESS

I

JULY 2004

I

45

Root Cause Analysis

For

Beginners

by James J. Rooney and Lee N. Vanden Heuvel

oot cause analysis (RCA) is a process

designed for use in investigating and cate-

gorizing the root causes of events with safe-

ty, health, environmental, quality, reliability and

production impacts. The term “event” is used to

generically identify occurrences that produce or

have the potential to produce these types of conse-

quences.

Simply stated, RCA is a tool designed to help

identify not only what and how an event occurred,

but also why it happened. Only when investiga-

tors are able to determine why an event or failure

occurred will they be able to specify workable

corrective measures that prevent future events of

the type observed.

Understanding why an event occurred is the

key to developing effective recommendations.

Imagine an occurrence during which an opera-

tor is instructed to close valve A; instead, the

operator closes valve B. The typical investiga-

tion would probably conclude operator error

was the cause.

This is an accurate description of what hap-

pened and how it happened. However, if the ana-

lysts stop here, they have not probed deeply

enough to understand the reasons for the mistake.

Therefore, they do not know what to do to pre-

vent it from occurring again.

In the case of the operator who turned the

wrong valve, we are likely to see recommenda-

tions such as retrain the operator on the proce-

dure, remind all operators to be alert when

R

QUALITY BASICS

In 50 Words

Or Less

• Root cause analysis helps identify what, how

and why something happened, thus preventing

recurrence.

• Root causes are underlying, are reasonably

identifiable, can be controlled by management

and allow for generation of recommendations.

• The process involves data collection, cause

charting, root cause identification and recom-

mendation generation and implementation.

manipulating valves or emphasize to all personnel

that careful attention to the job should be main-

tained at all times. Such recommendations do little

to prevent future occurrences.

Generally, mistakes do not just happen but can

be traced to some well-defined causes. In the case

of the valve error, we might ask, “Was the proce-

dure confusing? Were the valves clearly labeled?

Was the operator familiar with this particular

task?”

The answers to these and other questions will

help determine why the error took place and

what the organization can do to prevent recur-

rence. In the case of the valve error, example

recommendations might include revising the

procedure or performing procedure validation to

ensure references to valves match the valve labels

found in the field.

Identifying root causes is the key to preventing

similar recurrences. An added benefit of an effective

RCA is that, over time, the root causes identified

across the population of occurrences can be used to

target major opportunities for improvement.

If, for example, a significant number of analyses

point to procurement inadequacies, then resources

can be focused on improvement of this management

system. Trending of root causes allows development

of systematic improvements and assessment of the

impact of corrective programs.

Definition

Although there is substantial debate on the defi-

nition of root cause, we use the following:

1. Root causes are specific underlying causes.

2. Root causes are those that can reasonably be

identified.

3. Root causes are those management has control

to fix.

4. Root causes are those for which effective rec-

ommendations for preventing recurrences can

be generated.

Root causes are underlying causes. The investi-

gator’s goal should be to identify specific underly-

ing causes. The more specific the investigator can

be about why an event occurred, the easier it will

be to arrive at recommendations that will prevent

recurrence.

Root causes are those that can reasonably be

identified. Occurrence investigations must be cost

beneficial. It is not practical to keep valuable man-

power occupied indefinitely searching for the root

causes of occurrences. Structured RCA helps ana-

lysts get the most out of the time they have invest-

ed in the investigation.

Root causes are those over which management

has control. Analysts should avoid using general

cause classifications such as operator error, equip-

ment failure or external factor. Such causes are not

specific enough to allow management to make

effective changes. Management needs to know

exactly why a failure occurred before action can be

taken to prevent recurrence.

We must also identify a root cause that manage-

ment can influence. Identifying “severe weather”

as the root cause of parts not being delivered on

time to customers is not appropriate. Severe weath-

er is not controlled by management.

Root causes are those for which effective recom-

mendations can be generated. Recommendations

should directly address the root causes identified

during the investigation. If the analysts arrive at

vague recommendations such as, “Improve adher-

ence to written policies and procedures,” then

they probably have not found a basic and specific

enough cause and need to expend more effort in the

analysis process.

Four Major Steps

The RCA is a four-step process involving the fol-

lowing:

1. Data collection.

2. Causal factor charting.

46

I

JULY 2004

I

www.asq.org

QUALITY BASICS

Identifying “severe weather”

as the root cause of parts not

being delivered on time to

customers is not appropriate.

QUALITY PROGRESS

I

JULY 2004

I

47

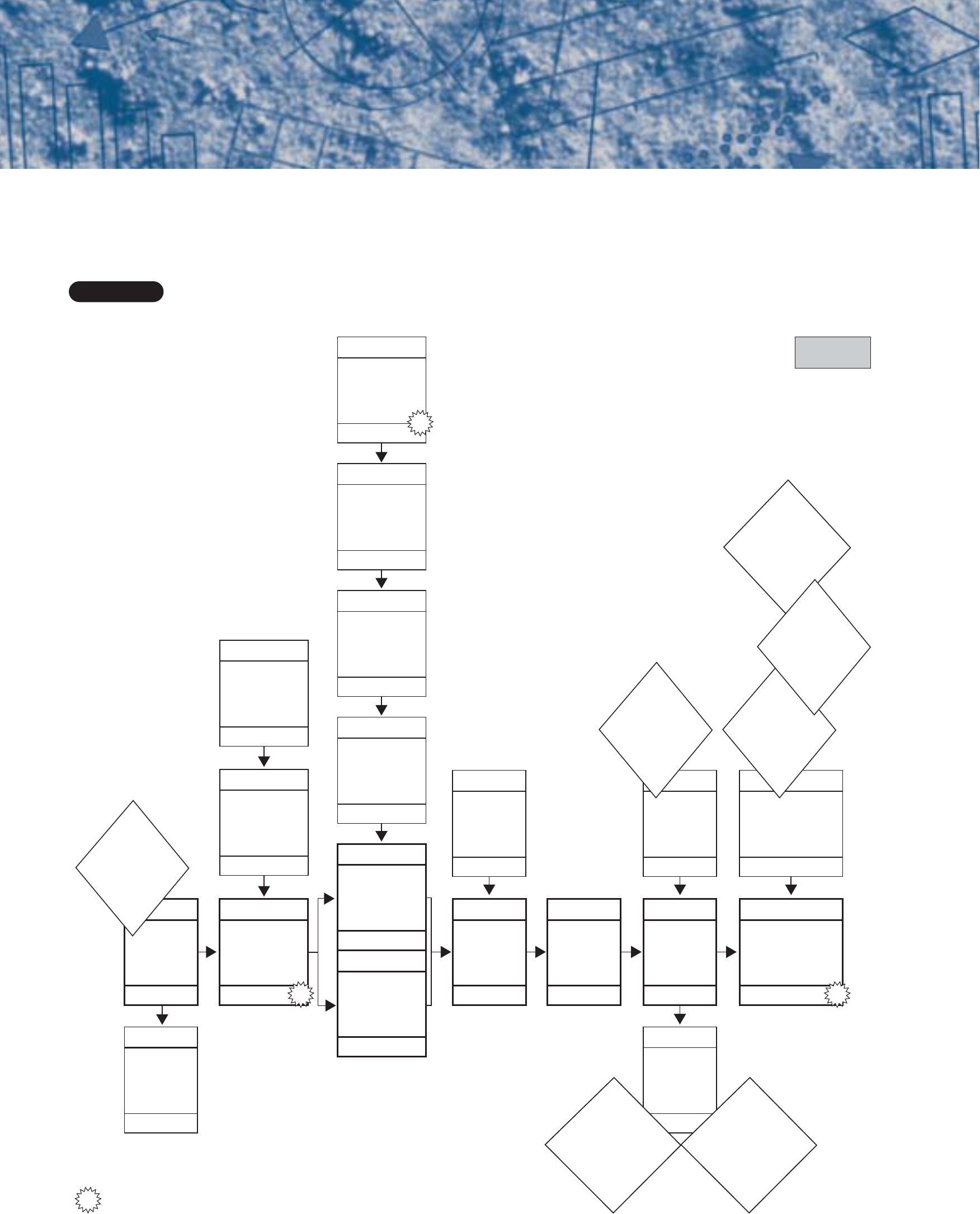

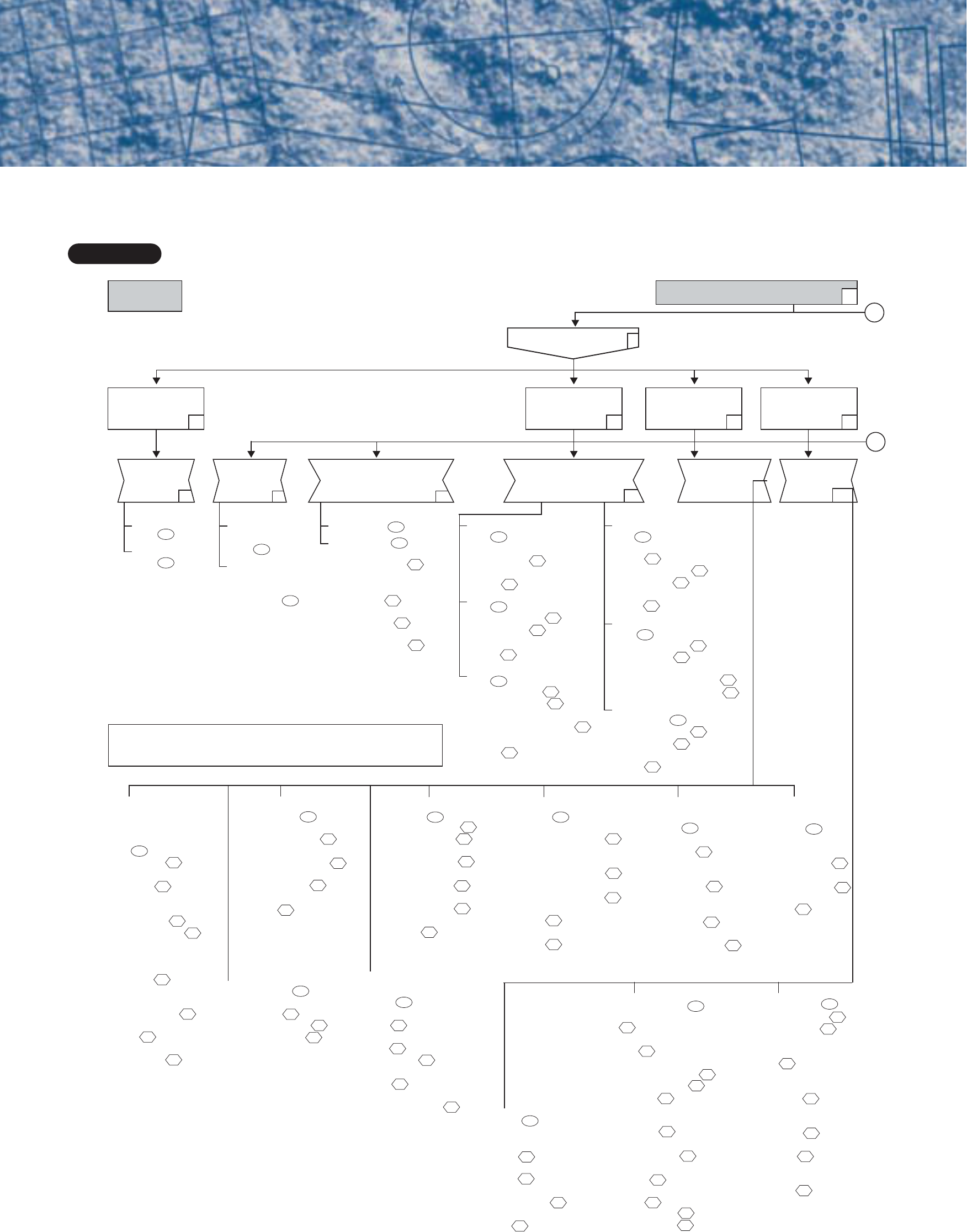

Causal Factor Chart

FIGURE 1

Aluminum

melts,

forming

hole in pan

Electric

burner

shorts out

Grease ignites

when it

contacts

burner

Fire starts

on the

stove

Mary meets

with Jane

Arcing heats

bottom of

aluminum

pan

Mary leaves

the frying

chicken

unattended

Jane rings

the doorbell

Jane comes

to the door

Mary

begins

frying

chicken

Mary

uses an

aluminum

pan

CF

CF

Mary

Pan

Jane

Jane, Mary

Mary

Burner

Pan

Pan

Conclusion

Mary

Mary

10 minutes

Fire

generates

smoke

Assumed

Mary runs

into the

kitchen

Mary

Smoke

detector

alarms

Jane, Mary

About 5:10 pm

Fire extinguisher

is not

charged

Mary

Fire extinguisher

does not

operate when

Mary tries to use it

Mary

Mary pulls

the plug

on the fire

extinguisher

Mary

Mary sees

the fire

on the stove

Mary

Mary tries

to use

the fire

extinguisher

Mary

CF

How

much oil is

used? How

much chicken?

Chicken,

pan, oil

What

exactly

did she see?

Mary

Had it

been

previously used?

Inspection tag

Had it

not been

originally charged?

Fire

extinguisher

Had it

leaked?

Fire extinguisher,

floor

Does Mary

know how

to use a fire

extinguisher?

Mary

Is "plug"

the same

as pin?

Mary

Part one

CF = Causal factor

5:00 pm

Figure 1 continued on next page

48

I

JULY 2004

I

www.asq.org

3. Root cause identification.

4. Recommendation generation and implementa-

tion.

Step one—data collection. The first step in the

analysis is to gather data. Without complete infor-

mation and an understanding of the event, the

causal factors and root causes associated with the

event cannot be identified. The majority of time

spent analyzing an event is spent in gathering

data.

Step two—Causal factor charting. Causal factor

charting provides a structure for investigators to orga-

nize and analyze the information gathered during

the investigation and identify gaps and deficiencies

in knowledge as the investigation progresses. The

causal factor chart is simply a sequence diagram

with logic tests that describes the events leading up

to an occurrence, plus the conditions surrounding

these events (see Figure 1, p. 47).

Preparation of the causal factor chart should

begin as soon as investigators start to collect infor-

mation about the occurrence. They begin with a

skeleton chart that is modified as more relevant

facts are uncovered. The causal factor chart should

drive the data collection process by identifying

data needs.

Data collection continues until the investigators

are satisfied with the thoroughness of the chart

(and hence are satisfied with the thoroughness of

the investigation). When the entire occurrence has

been charted out, the investigators are in a good

position to identify the major contributors to the

incident, called causal factors. Causal factors are

those contributors (human errors and component

failures) that, if eliminated, would have either pre-

vented the occurrence or reduced its severity.

In many traditional analyses, the most visible

causal factor is given all the attention. Rarely, how-

ever, is there just one causal factor; events are usu-

ally the result of a combination of contributors.

When only one obvious causal factor is addressed,

the list of recommendations will likely not be com-

plete. Consequently, the occurrence may repeat

itself because the organization did not learn all that

it could from the event.

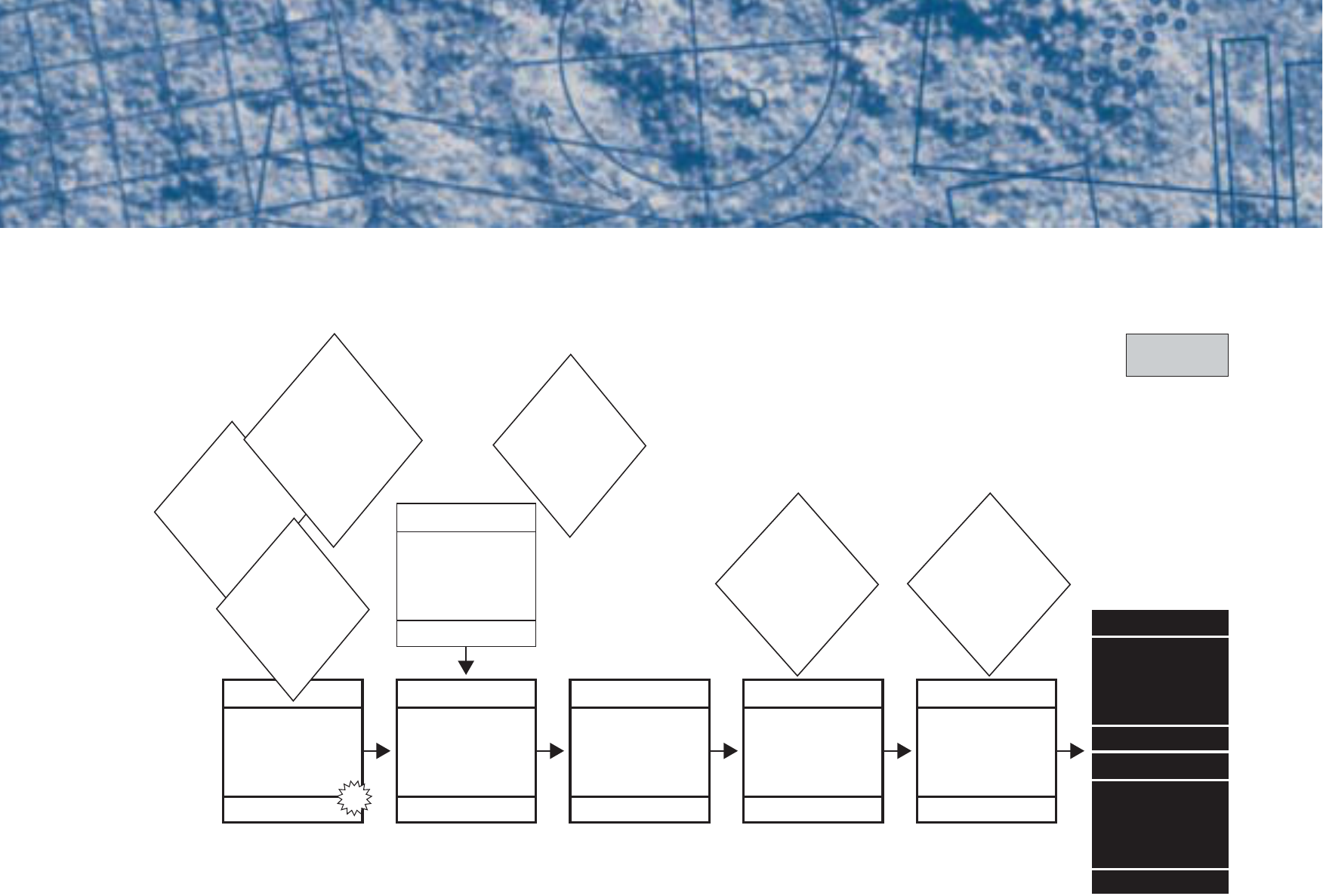

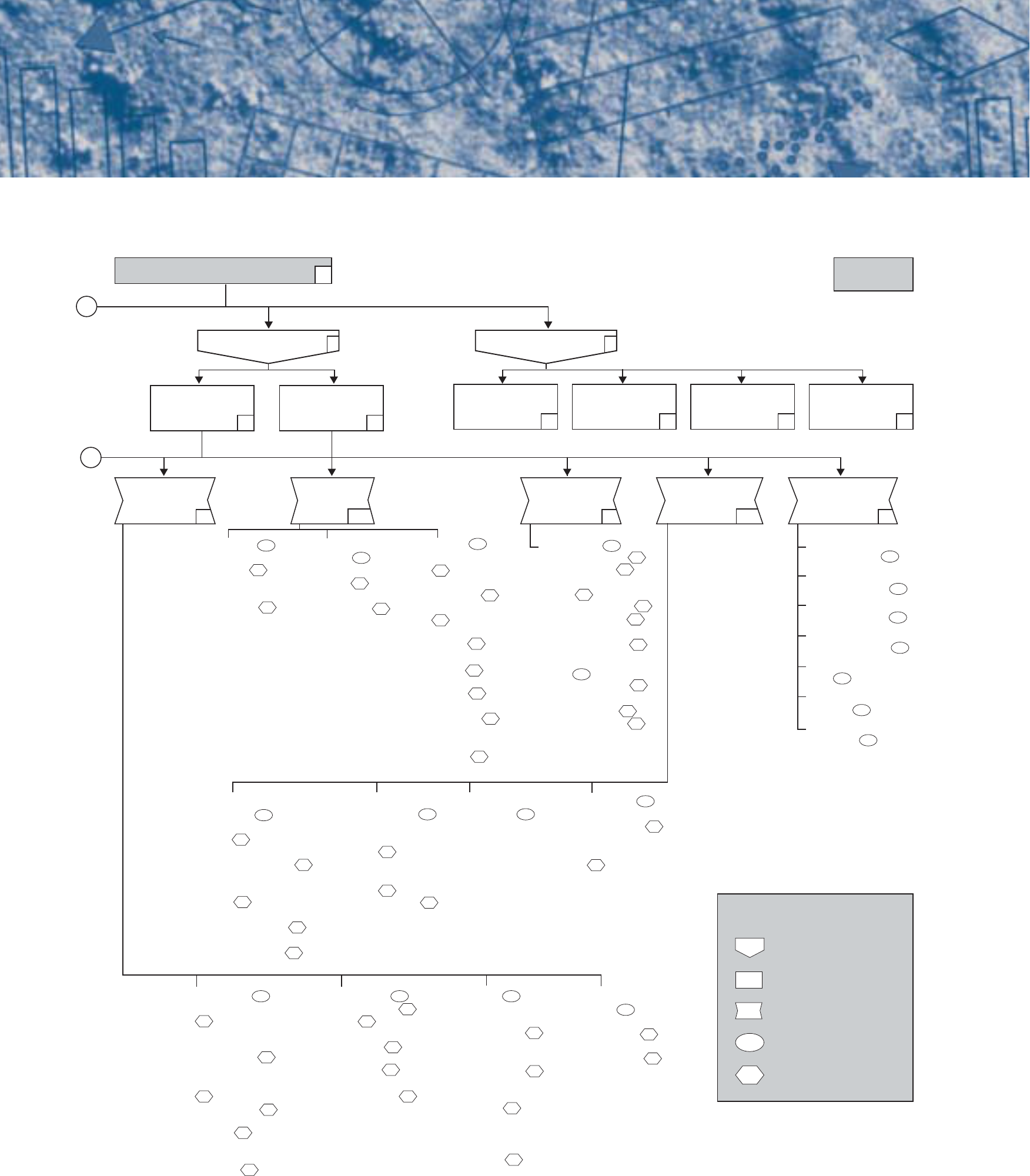

Step three—root cause identification. After all

the causal factors have been identified, the investi-

gators begin root cause identification. This step

QUALITY BASICS

Part two

Fire spreads

throughout

the kitchen

Kitchen, Mary

Mary throws

water on

the fire

Mary

Mary calls the

fire department

Mary, FD

Fire department

arrives

Observation

Fire department

puts out fire

FD, observation

Kitchen

destroyed

by fire

Other losses

from smoke and

water damage?

Time?Time?Time?

CF

Fire was a

grease fire

Mary, pan

Did she do

anything else?

Mary

Was Mary

trying to do this?

Mary

Did she know

this was wrong?

Lack of practice

fighting fires?

Mary

What is

Jane doing during

this time?

Mary, Jane

How long

did it take for the

FD to arrive?

FD

dispatcher

Did the FD

use the correct

techniques?

FD

QUALITY PROGRESS

I

JULY 2004

I

49

involves the use of a decision diagram called the

Root Cause Map (see Figure 2, p. 50) to identify the

underlying reason or reasons for each causal factor.

The map structures the reasoning process of the

investigators by helping them answer questions

about why particular causal factors exist or

occurred. The identification of root causes helps

the investigator determine the reasons the event

occurred so the problems surrounding the occur-

rence can be addressed.

Step four—recommendation generation and

implementation. The next step is the generation of

recommendations. Following identification of the

root causes for a particular causal factor, achievable

recommendations for preventing its recurrence are

then generated.

The root cause analyst is often not responsible

for the implementation of recommendations gener-

ated by the analysis. However, if the recommenda-

tions are not implemented, the effort expended in

performing the analysis is wasted. In addition, the

events that triggered the analysis should be expect-

ed to recur. Organizations need to ensure that rec-

ommendations are tracked to completion.

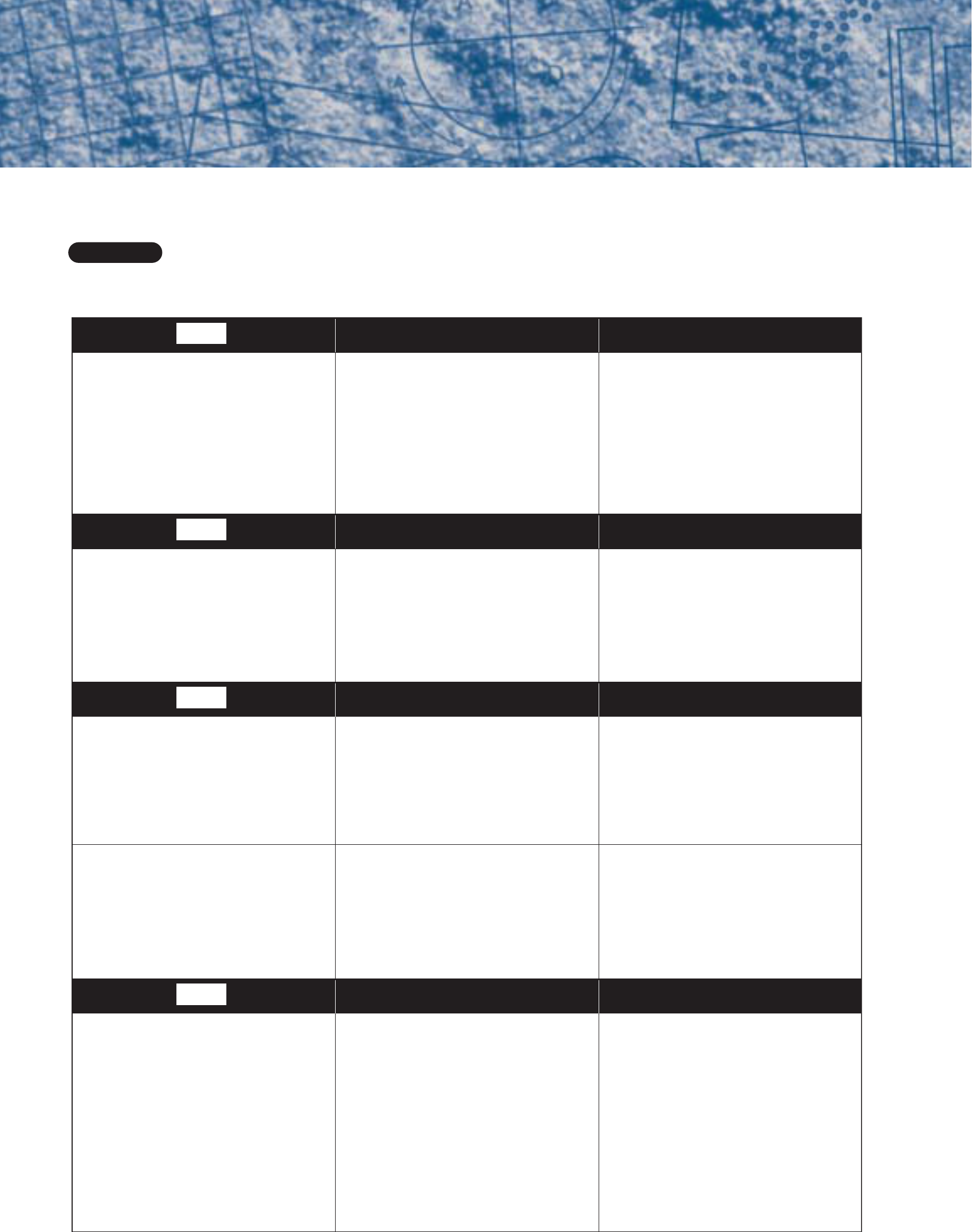

Presentation of Results

Root cause summary tables (see Table 1, p. 52)

can organize the information compiled during data

analysis, root cause identification and recommen-

dation generation. Each column represents a major

aspect of the RCA process.

•In the first column, a general description of the

causal factor is presented along with sufficient

background information for the reader to be

able to understand the need to address this

causal factor.

• The second column shows the Path or Paths

through the Root Cause Map associated with

the causal factor.

• The third column presents recommendations

to address each of the root causes identified.

Use of this three-column format aids the investi-

gator in ensuring root causes and recommenda-

tions are developed for each causal factor.

The end result of an RCA investigation is gener-

ally an investigation report. The format of the

report is usually well defined by the administrative

documents governing the particular reporting sys-

tem, but the completed causal factor chart and

causal factor summary tables provide most of the

information required by most reporting systems.

Example Problem

The following example is nontechnical, allowing

the reader to focus on the analysis process and not

the technical aspects of the situation. The following

narrative is the account of the event according to

Mary:

It was 5 p.m. I was frying chicken. My friend

Jane stopped by on her way home from the doc-

tor, and she was very upset. I invited her into

the living room so we could talk. After about 10

minutes, the smoke detector near the kitchen

came on. I ran into the kitchen and found a fire

on the stove. I reached for the fire extinguisher

and pulled the plug. Nothing happened. The

fire extinguisher was not charged. In despera-

tion, I threw water on the fire. The fire spread

throughout the kitchen. I called the fire depart-

ment, but the kitchen was destroyed. The fire

department arrived in time to save the rest of

the house.

Data gathering began as soon as possible after

the event to prevent loss or alteration of the data.

The RCA team toured the area as soon as the fire

department declared it safe. Because data from

people are the most fragile, Mary, Jane and the fire-

fighters were interviewed immediately after the

fire. Photographs were taken to record physical

and position data.

The analysts then developed the causal factor

chart (see Figure 1, p. 47) to clearly define the

sequence of events that led to the fire. The causal

factor chart begins with the event; Mary begins fry-

ing chicken at 5 p.m. As the chart develops from

In many traditional analyses,

the most visible causal factor

is given all the attention.

50

I

JULY 2004

I

www.asq.org

QUALITY BASICS

Root Cause Map

FIGURE 2

Section one

1

2

Start here with each causal factor.

1

6

Equipment

reliability program

problem

7

Installation/

fabrication

8

Equipment

misuse

2

Equipment difficulty

Corrective maintenance

LTA

• Troubleshooting/corrective

action LTA

• Repair implementation

LTA

Preventive maintenance

LTA

• Frequency LTA

• Scope LTA

• Activity implementation

LTA

Predictive maintenance

LTA

• Detection LTA

• Monitoring LTA

• Troubleshooting/

corrective action LTA

• Activity implementation

LTA

29

32

36

30

31

33

34

35

37

38

39

40

Proactive maintenance

LTA

• Event specification

LTA

• Monitoring LTA

• Scope LTA

• Activity implementation

LTA

Failure finding maintenance

LTA

• Frequency LTA

• Scope LTA

• Troubleshooting/

corrective action LTA

• Repair implementation

Routine equipment

rounds LTA

• Frequency LTA

• Scope LTA

• Activity implementation

LTA

41

42

43

44

45

47

48

49

50

52

53

54

46

51

Equipment reliability

program implementation

LTA

28

Procedures

111

No program

Program LTA

• Analysis/design

procedure LTA

• Inappropriate type

of maintenance

assigned

• Risk acceptance

criteria LTA

• Allocation of

resources LTA

22

23

24

25

26

27

Equipment reliability

program design

less than adequate (LTA)

21

16

Design input

LTA

Design output

LTA

17

Design input/

output

15

Equipment

design records

LTA

Equipment

operating/

maintenance

history LTA

19

20

Equipment

records

18

Administrative/

management

systems

55

Note: Node numbers correspond to matching page in Appendix A of the

Root Cause Analysis Handbook.

Customer

interface/

services

• Customer

requirements

not identified

• Customer needs

not addressed

• Implementation

LTA

106

108

109

110

Document and

configuration

control

• Change not

identified

• Verification of design/

field changes LTA

(no PSSR*)

• Documentation

content not kept

up to date

• Control of official

documents LTA

100

102

103

104

105

Procurement

control

• Purchasing

specifications LTA

• Control of changes

to procurement

specifications LTA

• Material acceptance

requirements LTA

• Material inspections

LTA

• Contractor selection

LTA

93

95

96

97

98

99

Product/material

control

• Handling LTA

• Storage LTA

• Packaging/

shipping LTA

• Unauthorized material

substitution

• Product acceptance

criteria LTA

• Product inspections

LTA

85

87

88

89

90

91

92

Safety/hazard/

risk review

• Review LTA or

not performed

• Recommendations not

yet implemented

• Risk acceptance

criteria LTA

• Review procedure

LTA

72

74

75

76

77

Standards,

policies or

administrative

controls (SPACs)

LTA

• No SPACs

• Not strict

enough

• Confusing,

contradictory or

incomplete

• Technical error

• Responsibility

for item/activity

not adequately

defined

• Planning, scheduling

or tracking of work

activities LTA

• Rewards/incentives

LTA

• Employee screening/

hiring LTA

57

59

60

61

62

63

64

65

66

SPACs not used

• Communication of

SPACs LTA

• Recently changed

• Enforcement LTA

67

69

70

71

Problem

identification

control

• Problem reporting

LTA

• Problem analysis

LTA

• Audits LTA

• Corrective action

LTA

• Corrective actions not

yet implemented

78

80

81

82

83

84

Not used

• Not available or

inconvenient to

obtain

• Procedure difficult

to use

• Use not required

but should be

• No procedure for

task

112

113

114

115

116

Misleading/confusing

• Format confusing or

LTA

• More than one action

per step

• No checkoff space

provided but should be

• Inadequate checklist

• Graphics LTA

• Ambiguous or confusing

instructions/

requirements

• Data/computations

wrong/incomplete

• Insufficient or excessive

references

• Identification of revised

steps LTA

• Level of detail LTA

• Difficult to identify

118

117

120

121

122

123

124

125

126

127

128

129

Wrong/incomplete

• Typographical error

• Sequence wrong

• Facts wrong/

requirements not

correct

• Wrong revision or

expired procedure

revision used

• Inconsistency

between

requirements

• Incomplete/situation

not covered

• Overlap or gaps

between

procedures

130

131

132

133

134

135

136

137

5

Equipment

design problem

Figure 2 continued on next page

QUALITY PROGRESS

I

JULY 2004

I

51

Section Two

Start here with each causal factor.

1

4

Other difficulty

1

3

Personal difficulty

9

Company

employee

10

Contract

employee

11

Natural

phenomena

12

Sabotage/

horseplay

13

External

events

14

Other

Training

163

Human factors

engineering

138

Communications

192

No training

• Decision not

to train

• Training

requirements not

identified

164

165

166

Training records

system LTA

• Training records

incorrect

• Training records

not up to date

167

168

169

Training LTA

• Job/task analysis

LTA

• Program design/

objectives LTA

• Lesson content

LTA

• On-the-job

training LTA

• Qualification

testing LTA

• Continuing

training LTA

• Training

resources LTA

• Abnormal events/

emergency

training LTA

170

171

172

174

175

176

177

178

179

Immediate

supervision

180

Preparation

• No preparation

• Job plan LTA

• Instructions to workers

LTA

• Walkthrough LTA

• Scheduling LTA

• Worker selection/

assignment LTA

Supervision during

work

• Supervision LTA

• Improper performance

not corrected

• Teamwork LTA

181

182

188

183

184

185

186

187

189

190

191

Personal

performance

208

Problem

detection LTA

*Sensory/perceptual

capabilities LTA

*Reasoning

capabilities LTA

*Motor/physical

capabilities LTA

*Attitude/attention

LTA

*Rest/sleep LTA

(fatigue)

*Personal/medication

problems

209

210

211

212

213

214

215

No communication or

not timely

• Method unavailable or

LTA

• Communication between

work groups LTA

• Communication between

shifts and management

LTA

• Communication with

contractors LTA

• Communication with

customers LTA

194

195

196

197

198

199

Misunderstood

communication

• Standard

terminology not

used

• Verification/

repeat back not

used

• Long message

200

201

202

203

Wrong

instructions

204

Job turnover LTA

• Communication

within shifts LTA

• Communication

between shifts

LTA

205

206

207

Workplace layout

• Controls/displays

LTA

• Control/display

integration/

arrangement LTA

• Location of

controls/displays

LTA

• Conflicting layouts

• Equipment

location LTA

• Labeling of

equipment or

locations LTA

140

141

143

144

145

146

147

Work environment

• Housekeeping LTA

• Tools LTA

• Protective clothing/

equipment LTA

• Ambient

conditions LTA

• Other environmental

stresses excessive

148

149

150

151

152

154

Workload

• Excessive control

action

requirements

• Unrealistic

monitoring

requirements

• Knowledge based

decision

required

• Excessive

calculation or

data manipulation

required

155

156

157

158

159

Intolerant

system

• Errors not

detectable

• Errors not

correctable

160

162

161

2

© 1995, 1997, 1999, 2000 and 2001, ABSG Consulting Inc.

*Note: These nodes are for descriptive

purposes only.

Shape Description

Primary difficulty source

Problem category

Root cause category

Near root cause

Root cause

*PSSR = Project scope summary report

52

I

JULY 2004

I

www.asq.org

QUALITY BASICS

Root Cause Summary Table

TABLE 1

Event description: Kitchen is destroyed by fire and damaged by smoke and water. Event #: 2003-1

Description:

Mary leaves the frying chicken unattended.

• Personnel difficulty.

• Administrative/management systems.

• Standards, policies or administrative

controls (SPACs) less than adequate (LTA).

• No SPACs.

• Implement a policy that hot oil is never left

unattended on the stove.

• Determine whether policies should be

developed for other types of hazards in the

facility to ensure they are not left unattended.

• Modify the risk assessment process or

procedure development process to address

requirements for personnel attendance

during process operations.

Paths Through Root Cause Map RecommendationsCausal factor # 1

Description:

Electric burner element fails (shorts out).

• Equipment difficulty.

• Equipment reliability program problem.

• Equipment reliability program design LTA.

• No program.

• Replace all burners on stove.

• Develop a preventive maintenance strategy

to periodically replace the burner elements.

• Consider alternative methods for preparing

chicken that may involve fewer hazards,

such as baking the chicken or purchasing

the finished product from a supplier.

Description:

Fire extinguisher does not operate when

Mary tries to use it.

• Equipment difficulty.

• Equipment reliability program problem.

• Equipment proactive maintenance LTA.

• Activity implementation LTA.

• Equipment difficulty.

• Equipment reliability program problem.

• Administrative/management systems.

• Problem identification and control LTA.

• Refill the fire extinguisher.

• Inspect other fire extinguishers in the

facility to ensure they are full.

• Have incident reports describing the use of

fire protection equipment routed to

maintenance to trigger refilling of the fire

extinguishers.

• Add this fire extinguisher to the audit list.

• Verify that all fire extinguishers are on the

quarterly fire extinguisher audit list.

• Have all maintenance work requests that

involve fire protection equipment routed to

the safety engineer so the quarterly

checklists can be modified as required.

Description:

Mary throws water on fire.

• Personnel difficulty.

• Company employee.

• Training.

• Training LTA.

• Abnormal events/emergency training LTA.

• Provide practical (hands-on) training

on the use of fire extinguishers. Classroom

training may be insufficient to adequately

learn this skill.

• Review other skill based activities to

ensure appropriate level of hands-on training

is provided.

• Review the training development process

to ensure adequate guidance is provided for

determining the proper training setting (for

example,classroom, lab, simulator, on the job

training, computer based training).

Paths Through Root Cause Map is a trademark of ABSG Consulting.

Paths Through Root Cause Map RecommendationsCausal factor # 2

Paths Through Root Cause Map RecommendationsCausal factor # 3

Paths Through Root Cause Map RecommendationsCausal factor # 4

left to right, the sequences begin to unfold. The loss

events—kitchen destroyed by fire and other losses

from smoke and water damage—are the shaded

rectangles in the causal factor chart.

Although we read the chart from left to right, it

is developed from right to left (backwards).

Development always starts at the end because that

is always a known fact. Logic and time tests are

used to build the chart back to the beginning of

the event. Numerous questions are usually gener-

ated that identify additional necessary data.

After the causal factor chart was complete (addi-

tional data were gathered to answer the questions

shown in Figure 1), the analysts identified the fac-

tors that influenced the course of events. There are

four causal factors for this event (see Table 1).

Elimination of these causal factors would have

either prevented the occurrence or reduced its sever-

ity. Note the recommendations in Table 1 are written

as if Mary’s house were an industrial facility.

Notice that causal factor two may be unexpect-

ed. It wasn’t overheating of the oil or splattering of

the oil that ignited the fire. If the wrong causal fac-

tor is identified, the wrong corrective actions will

be developed.

The application of the technique identified that

the electric burner element failed by shorting out.

The short melted Mary’s aluminum pan, releasing

the oil onto the hot burner, starting the fire.

The analyst must be willing to probe the data

first to determine what happened during the occur-

rence, second to describe how it happened, and

third to understand why.

BIBLIOGRAPHY

Accident/Incident Investigation Manual, second edition,

DOE/SSDC 76-45/27, Department of Energy.

Events and Causal Factors Charting, DOE/SSDC 76-45/14,

Department of Energy, 1985.

Ferry, Ted S., Modern Accident Investigation and Analysis, sec-

ond edition, John Wiley and Sons, 1988.

Guidelines for Investigating Chemical Process Incidents,

American Institute of Chemical Engineers, Center for

Chemical Process Safety, 1992.

Occupational Safety and Health Administration Accident

Investigation Course, Office of Training and Education, 1993.

Root Cause Analysis Handbook, WSRC-IM-91-3, Department of

Energy, 1991 (and earlier versions).

Root Cause Analysis Handbook: A Guide to Effective

Investigation, ABSG Consulting Inc., 1999.

User’s Guide for Reactor Incident Root Cause Coding Tree, revi-

sion five, DPST-87-209, E.I. duPont de Nemours, Savan-

nah River Laboratory, 1986.

JAMES J. ROONEY

is a senior risk and reliability engineer

with ABSG Consulting Inc.’s Risk Consulting Division in

Knoxville, TN. He earned a master’s degree in nuclear engi-

neering from the University of Tennessee. Rooney is a Fellow

of ASQ and an ASQ certified quality auditor, quality audi-

tor-hazard analysis and critical control points, quality engi-

neer, quality improvement associate, quality manager and

reliability engineer.

LEE N. VANDEN HEUVEL is a senior risk and reliability

engineer with ABSG Consulting Inc.’s Risk Consulting

Division in Knoxville, TN. He earned a master’s degree in

nuclear engineering from the University of Wisconsin.

Vanden Heuvel co-authored the Root Cause Analysis

Handbook: A Guide to Effective Incident Investiga-

tion, co-developed the RootCause Leader software and was

a co-author of the Center for Chemical Process Safety’s

Guidelines for Investigating Chemical Process

Incidents. He develops and teaches courses on the subject.

QUALITY PROGRESS

I

JULY 2004

I

53

comment

Please

If you would like to comment on this article,

please post your remarks on the

Quality Progress

Discussion Board at www.asq.org, or e-mail them