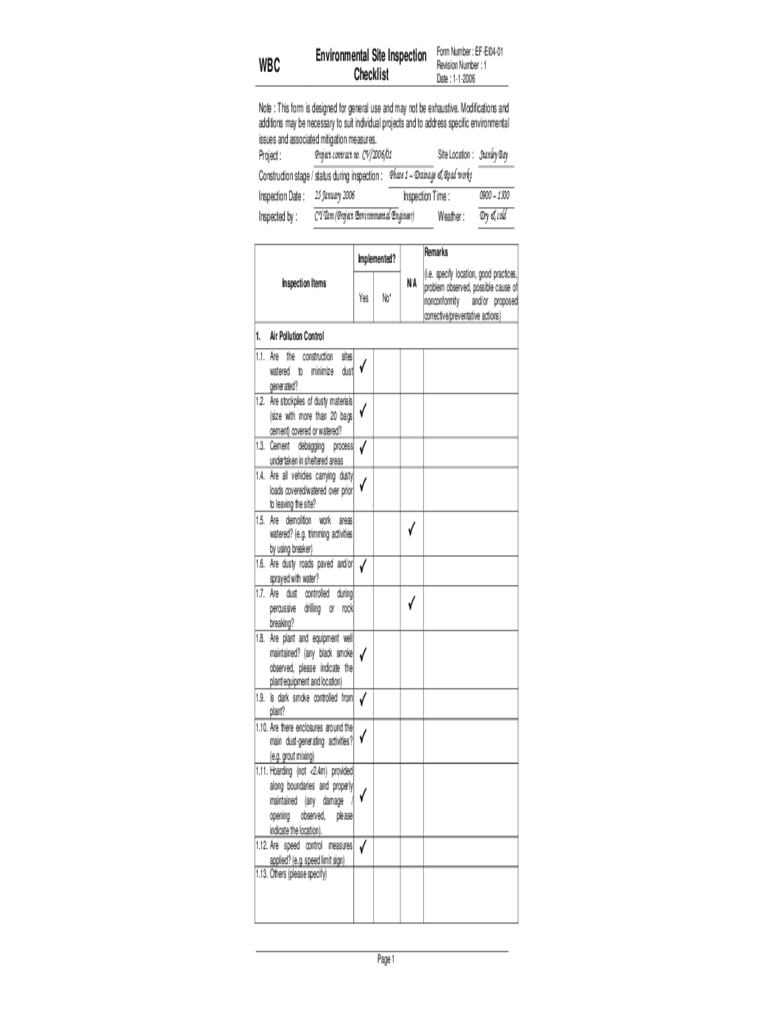

Fillable Printable Environmental Site Inspection Checklist Sample

Fillable Printable Environmental Site Inspection Checklist Sample

Environmental Site Inspection Checklist Sample

WBC

Environmenta l Site Inspection

Checklist

Form Number : EF-EI04-01

Revision Number : 1

Date : 1-1-2006

Page 1

Note : This form is designed for general use and may not be exhaustive. Modifications and

additions may be necessary to suit individual projects and to address specific environmental

issues and associated mitigation measures.

Project :

Project contract no. CV/2006/01

Site Location :

Stanley Bay

Construction stage / status during inspection :

Phase 1 – Drainage & Road works

Inspection Date :

25 January 2006

Inspection Time :

0900 – 1500

Inspected by :

CY Tam (Project Environmental Engineer)

Weather :

Dry & cold

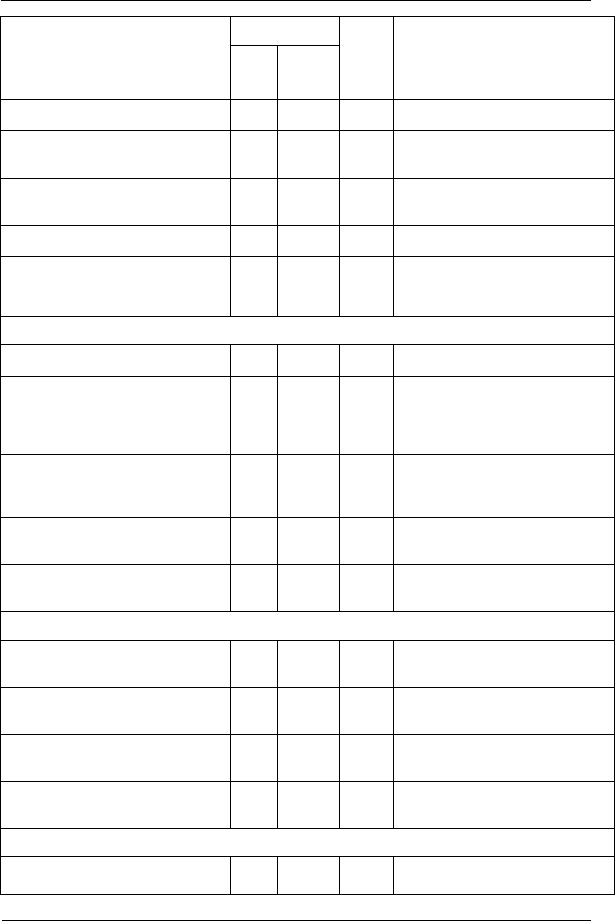

Inspection Items

Implemented?

N/A

Remarks

(i.e. specify location, good practices,

problem observed, possible cause of

nonconformity and/or proposed

corrective/preventative actions)

Yes No*

1. Air Pollution Control

1.1. Are the construction sites

watered to minimize dust

generated?

1.2. Are stockpiles of dusty materials

(size with more than 20 bags

cement) covered or watered?

1.3. Cement debagging process

undertaken in sheltered areas

1.4. Are all vehicles carrying dusty

loads covered/wa

tered over prior

to leaving the site?

1.5. Are demolition work areas

watered? (e.g. trimming activities

by using breaker)

1.6. Are dusty roads paved and/or

sprayed with water?

1.7. Are dust controlled during

percussive drilling or rock

breaking?

1.8. Are plant and equipment well

maintained? (any black smoke

observed, please indicate the

plant/equipment and location)

1.9. Is dark smoke controlled from

plant?

1.10. Are there enclosures around the

main dust-

generating activities?

(e.g. grout mixing)

1.11. Hoarding (not <2.4m) provided

along boundaries and properly

maintained (any damage /

opening observed, please

indicate the locatio n).

1.12. Are speed control measures

applied? (e.g. speed limit sign)

1.13. Others (please specify)

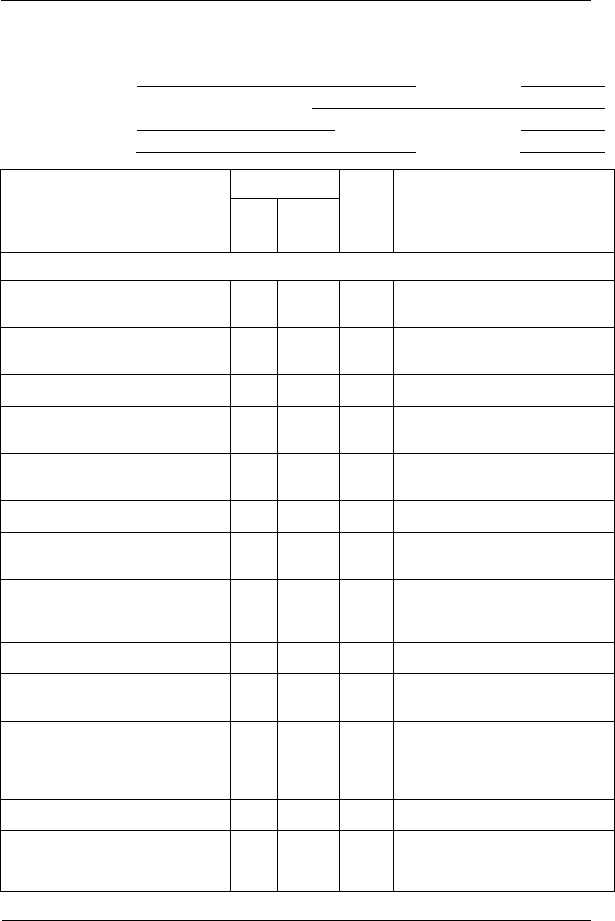

WBC

Environmenta l Site Inspection

Checklist

Form Number : EF-EI04-01

Revision Number : 1

Date : 1-1-2006

Page 2

Inspection Items

Implemented?

N/A

Remarks

(i.e. specify location, good practices,

problem observed, possible cause of

nonconformity and/or proposed

corrective/preventative actions)

Yes No*

2. Water Pollution Control

2.1. Are water discharge licenses

valid?

2.2. Are conditions of the license

compiled with? (check the

monitoring records and observe

physically)

2.3. Are wastewater tr eatment s ystem

being used and properly

maintained on

site? (e.g. des ilting

tank)

2.4. Are there any wastewater

discharged to t he stormdr ains?

Is

the wastewater being treated?

2.5. Are measures provided to

properly direct effluent to silt

removal facilities? (e.g. provide

earth bunds / U-channels)

2.6. Are u-channels and manholes

free of silt and sediment?

2.7. Are sedimentation traps and

tanks free of silt and sediment?

2.8. Are all manholes on-site covered

and sealed?

2.9. Are sandbags/earth bund

adopted to pr e ve nt wash in g a way

of sand/sil

t and wastewater to

drains, catchpit, public road and

footpath?

2.10. Are vehicles and plants cleaned

before leaving the site?

2.11. Are wheel washing facilities well

maintained to prevent overflow,

flooding sediment?

2.12. Is sand and silt settled out in

wheel washing bay and

removed?

2.13. Is the public road/area around the

site entrance and site hoarding

kept clean and free of muddy

water?

2.14. Is domestic water directed to

septic tanks or chemical toilets?

2.15. Others (please specify)

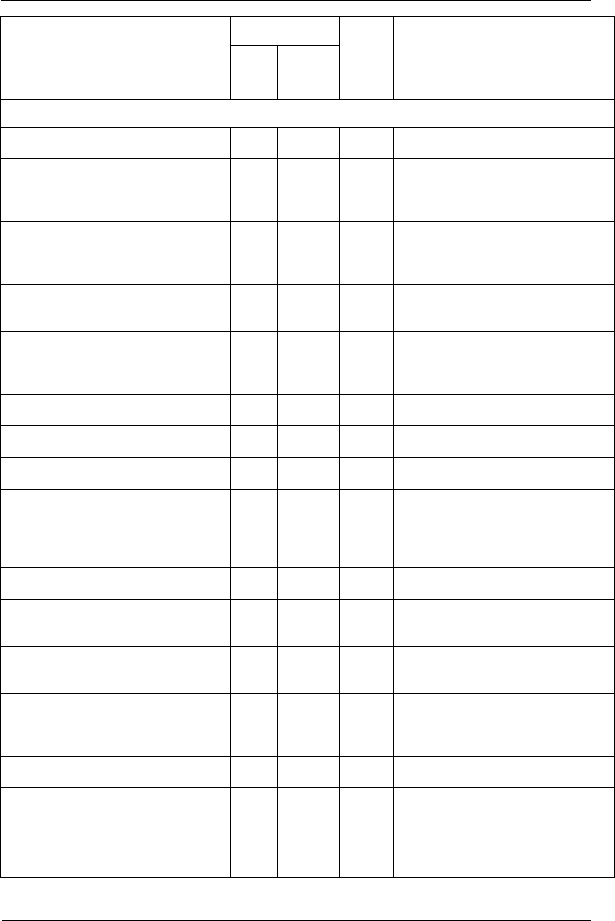

WBC

Environmenta l Site Inspection

Checklist

Form Number : EF-EI04-01

Revision Number : 1

Date : 1-1-2006

Page 3

Inspection Items

Implemented?

N/A

Remarks

(i.e. specify location, good practices,

problem observed, possible cause of

nonconformity and/or proposed

corrective/preventative actions)

Yes No*

3. Noise Control

3.1. Is the CNP (Construction Noise

Permit) valid for work during

restricted hours?

3.2. Are copies of the valid

Construction Noise Permits

posted at site entrance/exit?

3.3. Do air compressors and

generators operate with door

s

closed?

3.4. Is idle plant/equipment turned off

or throttled down?

3.5. Do air compressors and hand-

held breakers have valid noise

emission labels (NEL)?

3.6. Any noise mitigation measures

adopted (e.g. use noise barrier /

enclosure)?

3.7. Are silenced equipments utilized?

3.8. Others (please specify)

4. Waste Management

4.1. Is the site kept clean and tidy?

(e.g. litter free, good

housekeeping)

4.2. Are separate chutes used for

inert and non-inert wastes ?

4.3. Are separate d labelled containers

/ areas provided for facilitating

recycling and waste segregation?

4.4. Are construction wastes /

recyclable wastes and general

refuse removed off site regularly?

4.5. Are constructi on wastes co llected

and disposed of properly by

licensed collectors?

4.6. Are chemical wastes, if any,

collected and disposed of

properly by licensed co llec t or s ?

4.7. Does chemical waste producer

license covers all major chemical

wastes produced on site?

4.8. Are chemical wastes properly

stored and labelled?

4.9. Are oil drums and

plants/equipments provided with

drip trays?

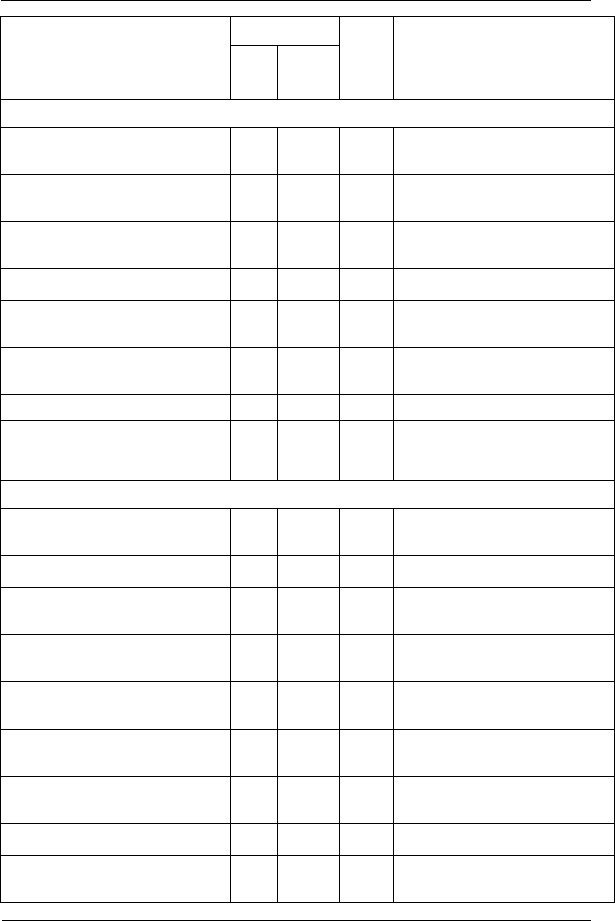

WBC

Environmenta l Site Inspection

Checklist

Form Number : EF-EI04-01

Revision Number : 1

Date : 1-1-2006

Page 4

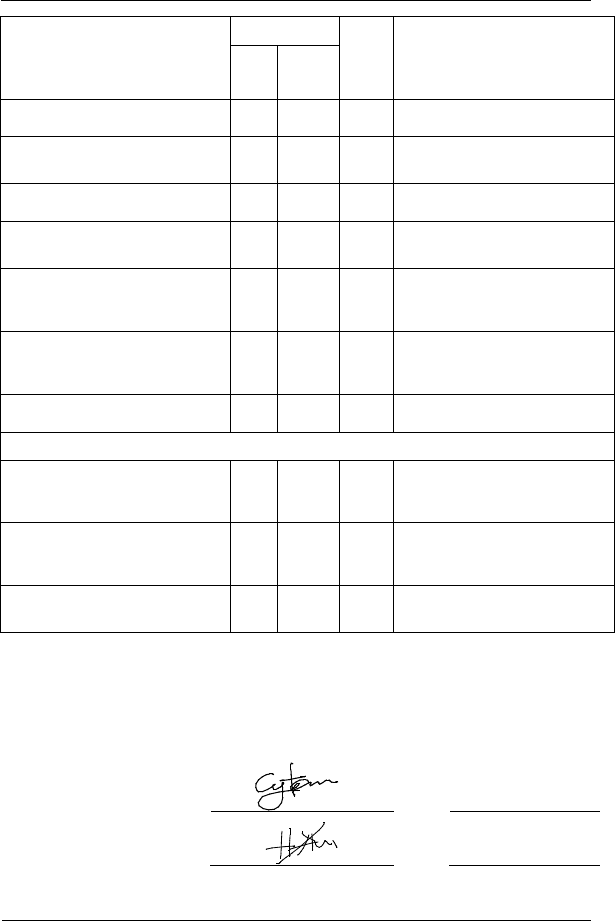

Inspection Items

Implemented?

N/A

Remarks

(i.e. specify location, good practices,

problem observed, possible cause of

nonconformity and/or proposed

corrective/preventative actions)

Yes No*

4.10. Are drip trays free of oil and

water?

4.11. Is there any oil spillage? Clean-

up the contaminated soil

immediately?

4.12. Is litter, foam or other

objectionable

matters in nearby

water drain/sewer cleaned?

4.13. Are asbestos wastes handled by

registered professionals?

4.14. Others (please specify)

5. Storage of Chemicals and Dangerous Goods

5.1. Are chemicals stored and

labelled proper l y?

5.2. Does storage of DG comply with

license conditions (include types

and quantities if DG store is

available, check the DG store

license)?

5.3. Are proper measures to control

oil spillage duri ng m aintenanc e or

to control other chemicals

spillage? (e.g. provide drip trays)

5.4. Are spill kits / sand / saw dust

used for absorbing chemical

spillage readily accessible?

5.5. Others (please specify)

6. Protection of Flora, Fauna and Historical Heritage

6.1. Are disturba nce to terrestri al flora

minimized (e.g. p

lants to be

preserved)?

6.2. Are disturbance to terrestrial

fauna minimized (if rare species

identified)?

6.3. Any historical heritage exists on

site? If yes, ensure

appropriate

measures taken to preserve it

6.4. Others (please specify)

7. Resource Conservatio n

7.1. Is water recycled wherever

possible for dust suppression?

WBC

Environmenta l Site Inspection

Checklist

Form Number : EF-EI04-01

Revision Number : 1

Date : 1-1-2006

Page 5

Inspection Items

Implemented?

N/A

Remarks

(i.e. specify location, good practices,

problem observed, possible cause of

nonconformity and/or proposed

corrective/preventative actions)

Yes No*

7.2. Is water pipe leakage and

wastage prevented?

7.3. Are diesel-powered plants and

equipments shut off while not in

use to reduce excessive use?

7.4. Are energy conservation

practices adopted?

7.5. Are metal or other alternatives

used to minimize the use of

timber?

7.6. Are materials stored in good

condition to prevent deterioration

and wastage (e.g. covered,

separated)?

7.7. Are pesticides used under the

requirement of Agriculture,

Fishers and Conservation

Department?

7.8. Others (please specify)

8. Emergency Preparedness and Response

8.1. Are fire extinguishers / fighting

facilities proper ly maintaine d and

not expired? Es cape not bloc ked

/ obstructed?

8.2. Are accidents and incidents

reported and reviewed, and

corrective & preventive actions

identified and recorded?

8.3. Others (please specify)

*Any “No” recorded represents the potential breach of regulation or improvement needed

and details of nonconformity (NC) shall be recorded in the Remarks.

* Report NC in the following forms. Each NC should make reference into the checklist as

coded. The responsible personnel shall identify the root cause of NC and adopt appropriate

corrective and preventive actions (CPA) for mitigation. Confirmation of the effectiveness of

the CPA shall be verified by Project Manager within an agreed time.

Signature of Site Inspector

Date

5 Jan 2006

Reviewed by Project Manager

Date

7 Jan 2006

WBC

Environmenta l Site Inspection

Checklist

Form Number : EF-EI04-01

Revision Number : 1

Date : 1-1-2006

Page 6

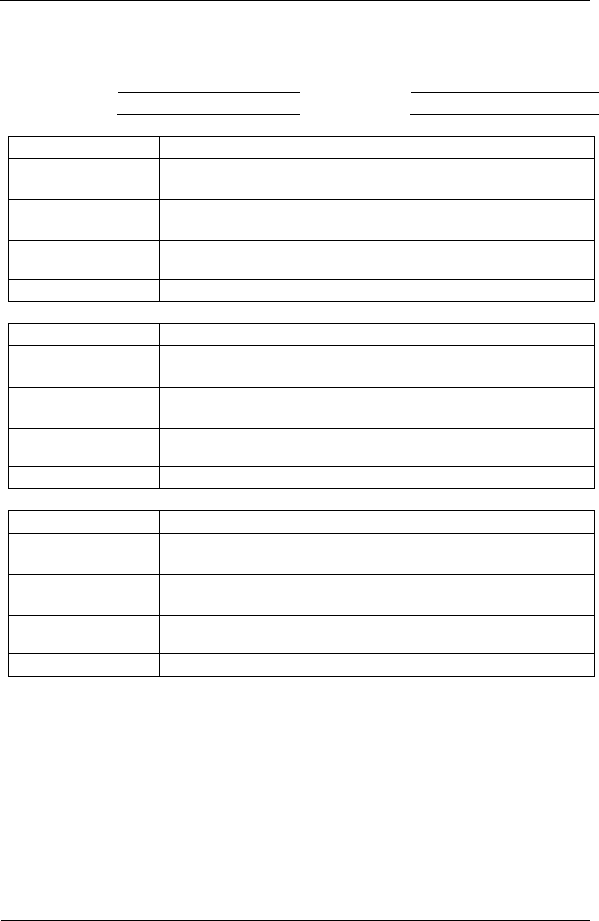

Improvement Request:

Project Site Location

Inspection Date

Inspected by

NC Reference

Descriptio n of NC

Root cause of NC

CPA adopted Target

completion date

Verified by PEO (Date)

NC Reference

Descriptio n of NC

Root cause of NC

CPA adopted Target

completion date

Verified by PEO (Date)

NC Reference

Descriptio n of NC

Root cause of NC

CPA adopted Target

completion date

Verified by PEO (Date)