Fillable Printable Fastener Torque Charts

Fillable Printable Fastener Torque Charts

Fastener Torque Charts

A55

FASTENER TORQUE CHARTS

Imperial has made a concerted effort to provide accurate information in its catalog and on its web site, however Imperial assumes no responsibility for the accuracy of the information. All information

published by Imperial in its catalog, marketing literature, and on its web site is provided "as is" without warranty, expressed or implied. Imperial and its vendors disclaim all warranties, expressed or

implied including, without limitation, warranties of merchandise and fitness for a particular purpose.

S

ize

C

laSS

N

ewtoN

M

eterS

F

oot

P

ouNdS

(

aPProx

.)

C

laSS

i

Mage

z

iNC

P

lated

u

NPlated

z

iNC

P

lated

u

NPlated

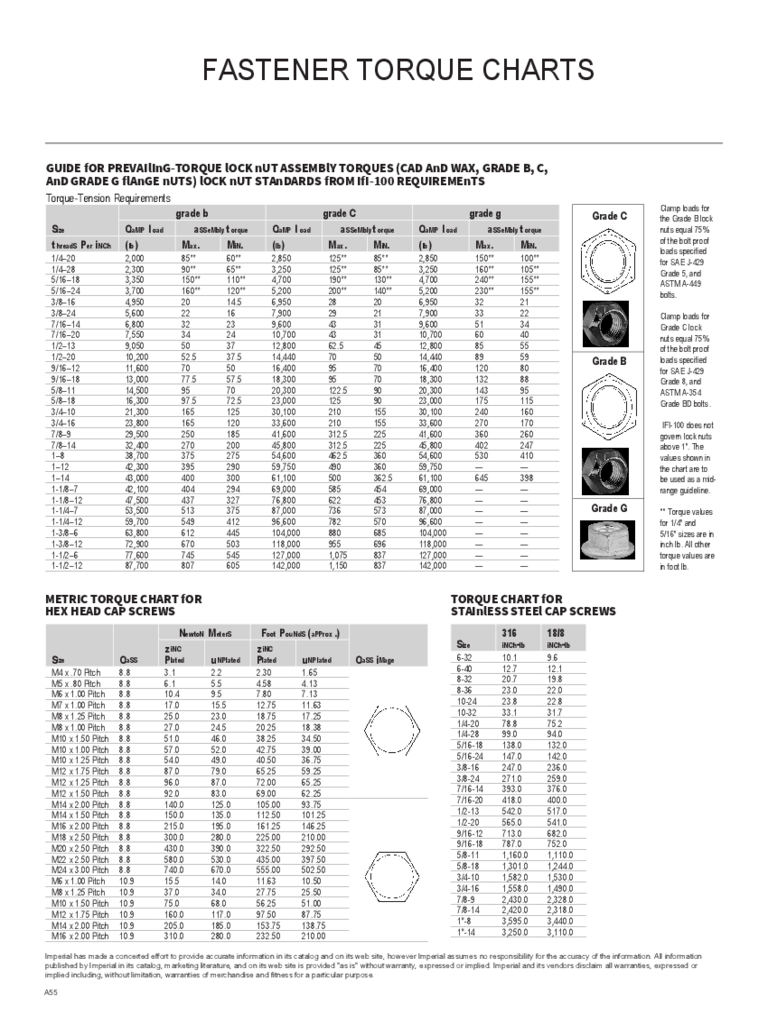

M4 x .70 Pitch 8.8 3.1 2.2 2.30 1.65

M5 x .80 Pitch 8.8 6.1 5.5 4.58 4.13

M6 x 1.00 Pitch 8.8 10.4 9.5 7.80 7.13

M7 x 1.00 Pitch 8.8 17.0 15.5 12.75 11.63

M8 x 1.25 Pitch 8.8 25.0 23.0 18.75 17.25

M8 x 1.00 Pitch 8.8 27.0 24.5 20.25 18.38

M10 x 1.50 Pitch 8.8 51.0 46.0 38.25 34.50

M10 x 1.00 Pitch 8.8 57.0 52.0 42.75 39.00

M10 x 1.25 Pitch 8.8 54.0 49.0 40.50 36.75

M12 x 1.75 Pitch 8.8 87.0 79.0 65.25 59.25

M12 x 1.25 Pitch 8.8 96.0 87.0 72.00 65.25

M12 x 1.50 Pitch 8.8 92.0 83.0 69.00 62.25

M14 x 2.00 Pitch 8.8 140.0 125.0 105.00 93.75

M14 x 1.50 Pitch 8.8 150.0 135.0 112.50 101.25

M16 x 2.00 Pitch 8.8 215.0 195.0 161.25 146.25

M18 x 2.50 Pitch 8.8 300.0 280.0 225.00 210.00

M20 x 2.50 Pitch 8.8 430.0 390.0 322.50 292.50

M22 x 2.50 Pitch 8.8 580.0 530.0 435.00 397.50

M24 x 3.00 Pitch 8.8 740.0 670.0 555.00 502.50

M6 x 1.00 Pitch 10.9 15.5 14.0 11.63 10.50

M8 x 1.25 Pitch 10.9 37.0 34.0 27.75 25.50

M10 x 1.50 Pitch 10.9 75.0 68.0 56.25 51.00

M12 x 1.75 Pitch 10.9 160.0 117.0 97.50 87.75

M14 x 2.00 Pitch 10.9 205.0 185.0 153.75 138.75

M16 x 2.00 Pitch 10.9 310.0 280.0 232.50 210.00

METRIC TORQUE CHART fOR

HEX HEAD CAP SCREWS

TORQUE CHART fOR

STAInlESS STEEl CAP SCREWS

S

ize

316

iNCh

-

lb

18/8

iNCh

-

lb

6-32 10.1 9.6

6-40 12.7 12.1

8-32 20.7 19.8

8-36 23.0 22.0

10-24 23.8 22.8

10-32 33.1 31.7

1/4-20 78.8 75.2

1/4-28 99.0 94.0

5/16-18 138.0 132.0

5/16-24 147.0 142.0

3/8-16 247.0 236.0

3/8-24 271.0 259.0

7/16-14 393.0 376.0

7/16-20 418.0 400.0

1/2-13 542.0 517.0

1/2-20 565.0 541.0

9/16-12 713.0 682.0

9/16-18 787.0 752.0

5/8-11 1,160.0 1,110.0

5/8-18 1,301.0 1,244.0

3/4-10 1,582.0 1,530.0

3/4-16 1,558.0 1,490.0

7/8-9 2,430.0 2,328.0

7/8-14 2,420.0 2,318.0

1"-8 3,595.0 3,440.0

1"-14 3,250.0 3,110.0

GUIDE fOR PREVAIlInG-TORQUE lOCK nUT ASSEMBlY TORQUES (CAD AnD WAX, GRADE B, C,

AnD GRADE G flAnGE nUTS) lOCK nUT STAnDARDS fROM IfI-100 REQUIREMEnTS

Torque-Tension Requirements

S

ize

grade b grade C grade g

C

laMP

l

oad

a

SSeMbly

t

orque

C

laMP

l

oad

a

SSeMbly

t

orque

C

laMP

l

oad

a

SSeMbly

t

orque

t

hreadS

P

er

i

NCh

(

lb

) M

ax

. M

iN

. (

lb

) M

ax

. M

iN

. (

lb

) M

ax

. M

iN

.

1/4–20 2,000 85** 60** 2,850 125** 85** 2,850 150** 100**

1/4–28 2,300 90** 65** 3,250 125** 85** 3,250 160** 105**

5/16–18 3,350 150** 110** 4,700 190** 130** 4,700 240** 155**

5/16–24 3,700 160** 120** 5,200 200** 140** 5,200 230** 155**

3/8–16 4,950 20 14.5 6,950 28 20 6,950 32 21

3/8–24 5,600 22 16 7,900 29 21 7,900 33 22

7/16–14 6,800 32 23 9,600 43 31 9,600 51 34

7/16–20 7,550 34 24 10,700 43 31 10,700 60 40

1/2–13 9,050 50 37 12,800 62.5 45 12,800 85 55

1/2–20 10,200 52.5 37.5 14,440 70 50 14,440 89 59

9/16–12 11,600 70 50 16,400 95 70 16,400 120 80

9/16–18 13,000 77.5 57.5 18,300 95 70 18,300 132 88

5/8–11 14,500 95 70 20,300 122.5 90 20,300 143 95

5/8–18 16,300 97.5 72.5 23,000 125 90 23,000 175 115

3/4–10 21,300 165 125 30,100 210 155 30,100 240 160

3/4–16 23,800 165 120 33,600 210 155 33,600 270 170

7/8–9 29,500 250 185 41,600 312.5 225 41,600 360 260

7/8–14 32,400 270 200 45,800 312.5 225 45,800 402 247

1–8 38,700 375 275 54,600 462.5 360 54,600 530 410

1–12 42,300 395 290 59,750 490 360 59,750 — —

1–14 43,000 400 300 61,100 500 362.5 61,100 645 398

1-1/8–7 42,100 404 294 69,000 585 454 69,000 — —

1-1/8–12 47,500 437 327 76,800 622 453 76,800 — —

1-1/4–7 53,500 513 375 87,000 736 573 87,000 — —

1-1/4–12 59,700 549 412 96,600 782 570 96,600 — —

1-3/8–6 63,800 612 445 104,000 880 685 104,000 — —

1-3/8–12 72,900 670 503 118,000 955 696 118,000 — —

1-1/2–6 77,600 745 545 127,000 1,075 837 127,000 — —

1-1/2–12 87,700 807 605 142,000 1,150 837 142,000 — —

Clamp loads for

the Grade B lock

nuts equal 75%

of the bolt proof

loads specified

for SAE J-429

Grade 5, and

ASTM A-449

bolts.

Clamp loads for

Grade C lock

nuts equal 75%

of the bolt proof

loads specified

for SAE J-429

Grade 8, and

ASTM A-354

Grade BD bolts.

IFI-100 does not

govern lock nuts

above 1". The

values shown in

the chart are to

be used as a mid-

range guideline.

** Torque values

for 1/4" and

5/16" sizes are in

inch lb. All other

torque values are

in foot lb.

Grade C

Grade B

Grade G

A56

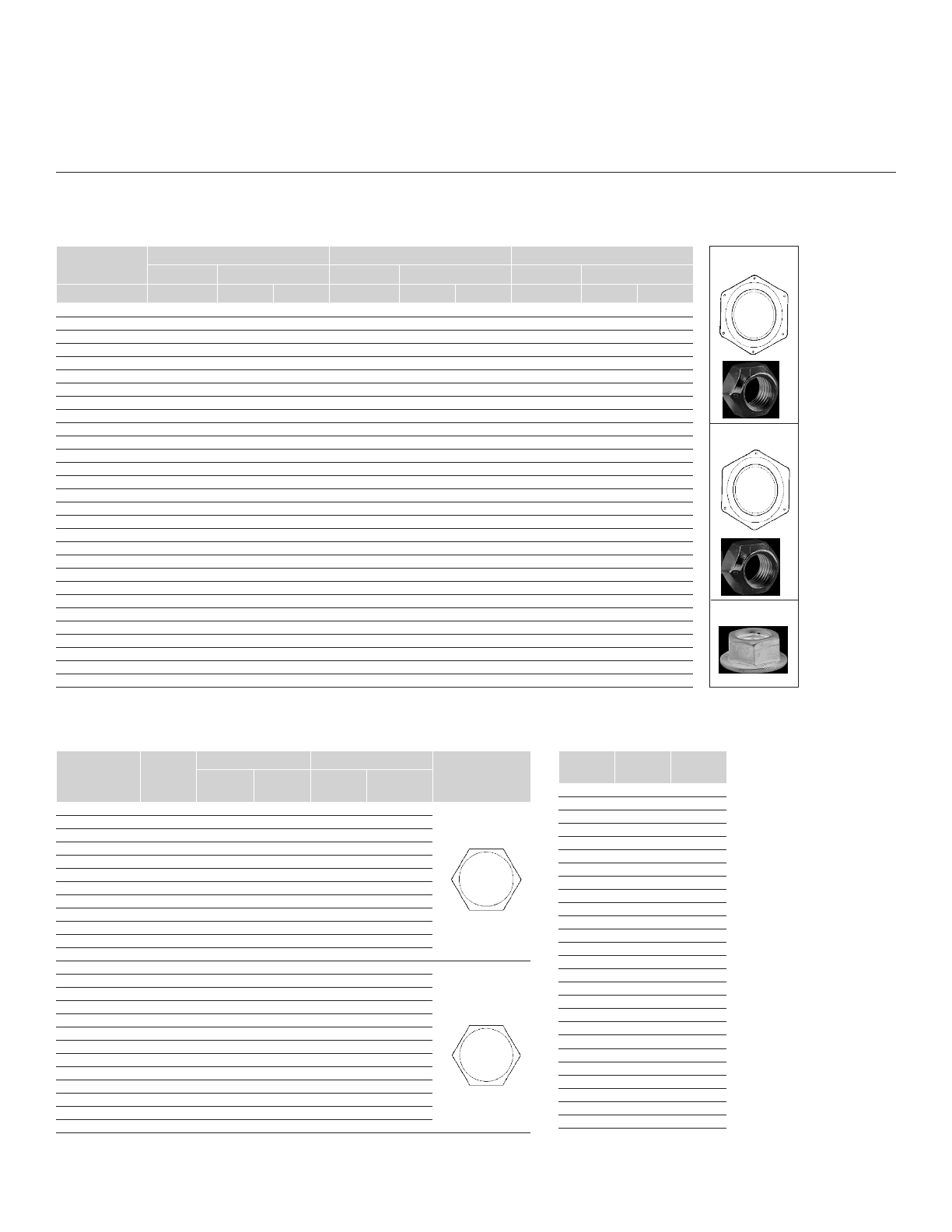

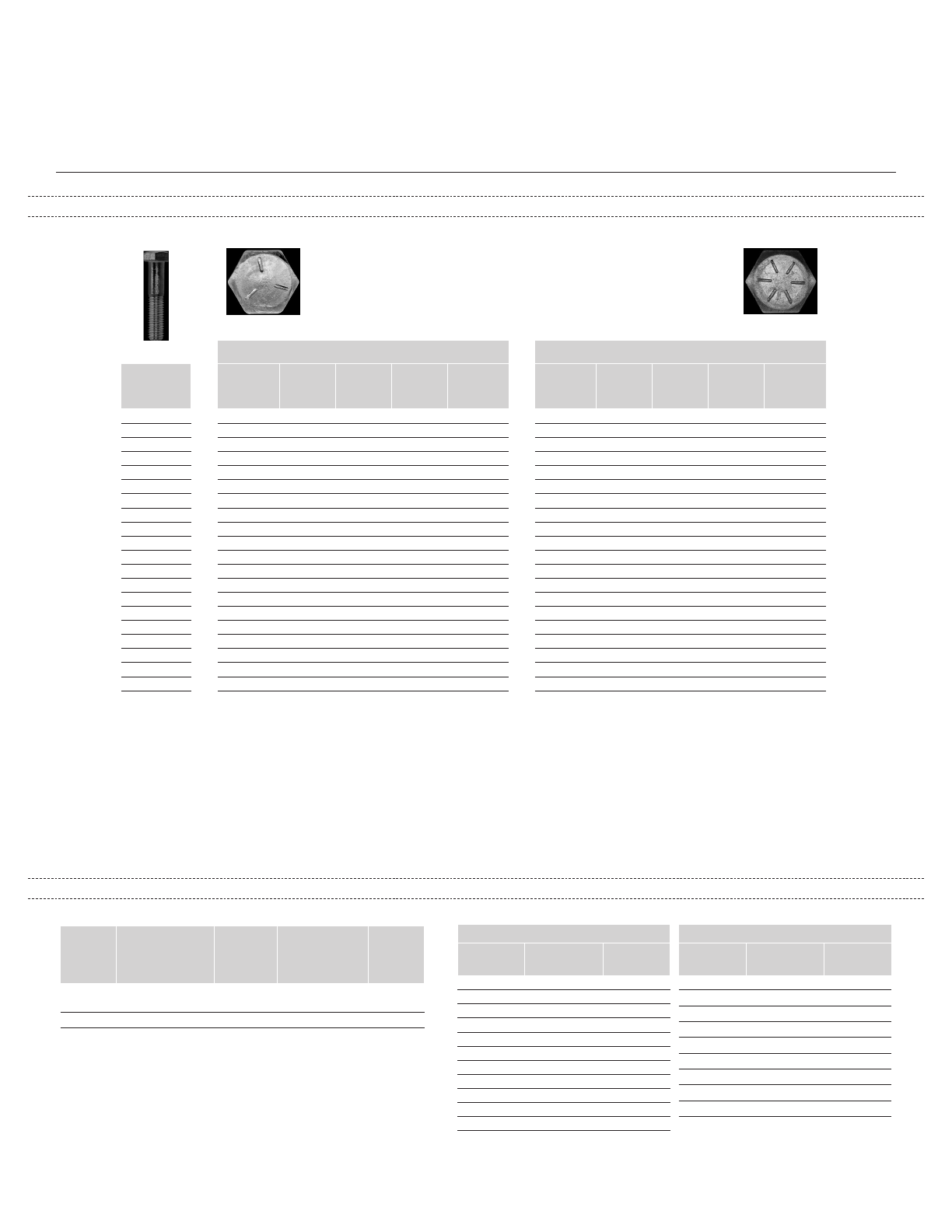

BOLT CLAMP LOADS

Imperial has made a concerted effort to provide accurate information in its catalog and on its web site, however Imperial assumes no responsibility for the accuracy of the information. All information

published by Imperial in its catalog, marketing literature, and on its web site is provided "as is" without warranty, expressed or implied. Imperial and its vendors disclaim all warranties, expressed or

implied including, without limitation, warranties of merchandise and fitness for a particular purpose.

NOTES:

The above recommended assembly torques are offered as a guide

only. Torque specifications, especially for critical joints, should

be determined under actual assembly conditions due to the many

variables involved which are difficult to predict and do affect the

torque-tension relationship.

The above recommended clamp loads are based on 75% of the

minimum specified proof loads for each grade and size.

d

iaMeter

& t

hreadS

P

er

i

NCh

1/4-20

1/4-28

5/16-18

5/16-24

3/8-16

3/8-24

7/16-14

7/16 20

1/2-13

1/2-20

9/16-12

9/16-18

5/8-11

5/8-18

3/4-10

3/4-16

7/8-9

7/8 14

1-8

1-14

uSS/Sae grade 5

t

eNSile

S

treNgth

M

iN

. Psi

P

rooF

l

oad

LB

C

laMP

l

oad

LB

t

orque

d

ry

Ft LB

l

ubriCated

Ft LB

120,000 2,700 2,020 8 6.3

120,000 3,100 2,320 10 7.2

120,000 4,450 3,340 17 13

120,000 4,900 3,700 19 14

120,000 6,600 4,950 30 23

120,000 7,450 5,600 35 25

120,000 9,050 6,780 50 35

120,000 10,100 7,570 55 40

120,000 12,100 9,050 75 55

120,000 13,600 10,200 85 65

120,000 15,500 11,600 110 80

120,000 17,300 12,950 120 90

120,000 19,200 14,400 150 110

120,000 21,800 16,350 170 130

120,000 28,400 21,300 260 200

120,000 31,700 23,780 300 220

120,000 39,300 29,450 430 320

120,000 43,300 32,450 470 350

120,000 51,500 38,600 640 480

120,000 57,700 43,300 720 540

uSS/ Sae grade 8

t

eNSile

S

treNgth

M

iN

. Psi

P

rooF

l

oad

LB

C

laMP

l

oad

LB

t

orque

d

ry

Ft LB

l

ubriCated

Ft LB

150,000 3,800 2,850 12 9

150,000 4,350 3,250 14 10

150,000 6,300 4,700 24 18

150,000 6,950 5,200 27 20

150,000 9,300 6,980 45 35

150,000 10,500 7,900 50 35

150,000 12,800 9,550 70 50

150,000 14,200 10,650 80 60

150,000 17,000 12,750 110 80

150,000 19,200 14,400 120 90

150,000 21,800 16,350 150 110

150,000 24,400 18,250 170 130

150,000 27,100 20,350 210 160

150,000 30,700 23,000 240 180

150,000 40,100 30,100 380 280

150,000 44,800 33,500 420 310

150,000 55,400 41,600 600 450

150,000 61,100 45,800 670 500

150,000 72,700 54,500 910 680

150,000 81,500 61,100 1,020 760

Torques for Grades 5 and 8 were calculated based on

the following relationship:

T = R D P

Where:T = Torque (ft lb)

D = Nominal Diameter (in)

P = Clamp Load (lb)

R = Tightening Coefficient

The value of R is assumed to be equal to .20 for dry, unplated

conditions and equal to .15 for lubricated, including plated,

conditions. Actual values of R can vary between .05 and .35 for

commonly encountered conditions.

SUGGESTED ASSEMBlY TORQUE VAlUES

When using anti-seize, reduce the lubed chart reading by 20% to properly torque.

Always lubricate and use lubed torque values.

S

treNgth

g

rade

a

PPliCable

S

izeS

P

rooF

l

oad

S

treSS

(

PSi

)

y

ield

S

treNgth

M

iN

. S

treSS

(

PSi

)

t

eNSile

S

treSS

M

iN

.

(

PSi

)

SAE Gr. 5

1/4 to 1" dia.

1" dia. to 1-1/2 dia.

85,000

74,000

92,000

81,000

120,000

105,000

SAE Gr. 8 1/4 to 1" dia. 120,000 130,000 150,000

Pounds to Inch Pound Conversion

lb x 12 = inch lb

Example: 9 lb x 12 = 108 inch lb

F

raCtioNal

M

eaSureMeNt

b

olt

d

iaMeter

C

aP

S

Crew

w

reNCh

S

ize

N

ut

w

reNCh

S

ize

1/4 7/16 7/16

5/16 1/2 1/2

3/8 9/16 9/16

7/16 5/8 11/16

1/2 3/4 3/4

9/16 13/16 7/8

5/8 15/16 15/16

3/4 1-1/8 1-1/8

7/8 1-5/16 1-5/16

1" 1-1/2 1-1/2

1-1/8 1-11/16 1-11/16

F

raCtioNal

M

eaSureMeNt

b

olt

d

iaMeter

C

aP

S

Crew

w

reNCh

S

ize

N

ut

w

reNCh

S

ize

1-1/4 1-7/8 1-7/8

1-3/8 2-1/16 2-1/16

1-1/2 2-1/4 2-1/4

1-3/4 2-5/8 2-5/8

2" 3" 3"

2-1/4 3-3/8 3-3/8

2-1/2 3-3/4 3-3/4

2-3/4 4-1/8 4-1/8

3" 4-1/2 4-1/2