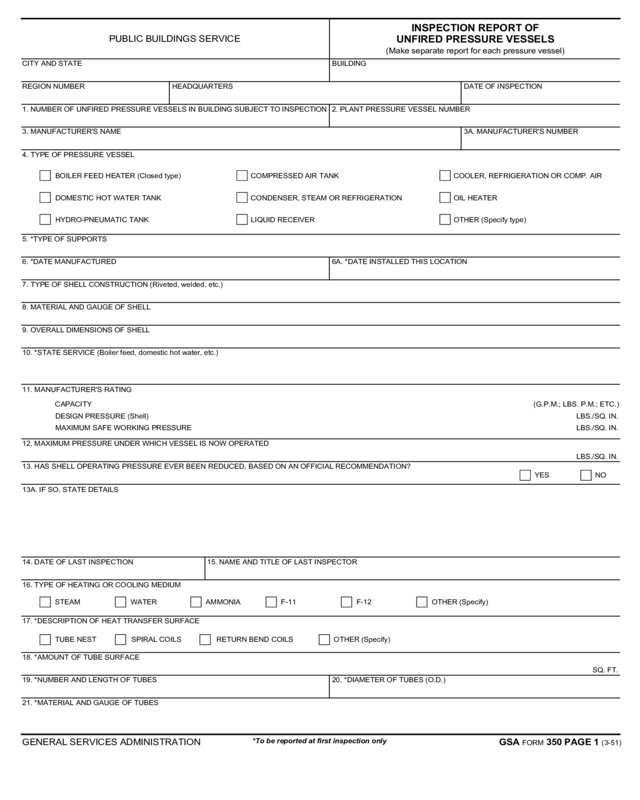

Fillable Printable Inspection Report Of Unfired Pressure Vessels

Fillable Printable Inspection Report Of Unfired Pressure Vessels

Inspection Report Of Unfired Pressure Vessels

PUBLIC BUILDINGS SERVICE

INSPECTION REPORT OF

UNFIRED PRESSURE VESSELS

(Make separate report for each pressure vessel)

CITY AND STATE

REGION NUMBER

3. MANUFACTURER'S NAME

4. TYPE OF PRESSURE VESSEL

5. *TYPE OF SUPPORTS

6. *DATE MANUFACTURED

7. TYPE OF SHELL CONSTRUCTION (Riveted, welded, etc.)

8. MATERIAL AND GAUGE OF SHELL

9. OVERALL DIMENSIONS OF SHELL

10. *STATE SERVICE (Boiler feed, domestic hot water, etc.)

11. MANUFACTURER'S RATING

12. MAXIMUM PRESSURE UNDER WHICH VESSEL IS NOW OPERATED

13. HAS SHELL OPERATING PRESSURE EVER BEEN REDUCED, BASED ON AN OFFICIAL RECOMMENDATION?

13A. IF SO, STATE DETAILS

14. DATE OF LAST INSPECTION

STEAMWATEROTHER (Specify)

TUBE NESTSPIRAL COILSRETURN BEND COILSOTHER (Specify)

F-12F-11AMMONIA

16. TYPE OF HEATING OR COOLING MEDIUM

17. *DESCRIPTION OF HEAT TRANSFER SURFACE

18. *AMOUNT OF TUBE SURFACE

19. *NUMBER AND LENGTH OF TUBES

21. *MATERIAL AND GAUGE OF TUBES

*To be reported at first inspection only

GENERAL SERVICES ADMINISTRATIONGSAFORM350PAGE 1(3-51)

20. *DIAMETER OF TUBES (O.D.)

15. NAME AND TITLE OF LAST INSPECTOR

CAPACITY

LBS./SQ. IN.

LBS./SQ. IN.

SQ. FT.

NOYES

LBS./SQ. IN.

(G.P.M.; LBS. P.M.; ETC.)

DESIGN PRESSURE (Shell)

MAXIMUM SAFE WORKING PRESSURE

6A. *DATE INSTALLED THIS LOCATION

BOILER FEED HEATER (Closed type)

LIQUID RECEIVER

CONDENSER, STEAM OR REFRIGERATION

COMPRESSED AIR TANK

OTHER (Specify type)

OIL HEATER

COOLER, REFRIGERATION OR COMP. AIR

DOMESTIC HOT WATER TANK

HYDRO-PNEUMATIC TANK

1. NUMBER OF UNFIRED PRESSURE VESSELS IN BUILDING SUBJECT TO INSPECTION

HEADQUARTERS

BUILDING

2. PLANT PRESSURE VESSEL NUMBER

DATE OF INSPECTION

3A. MANUFACTURER'S NUMBER

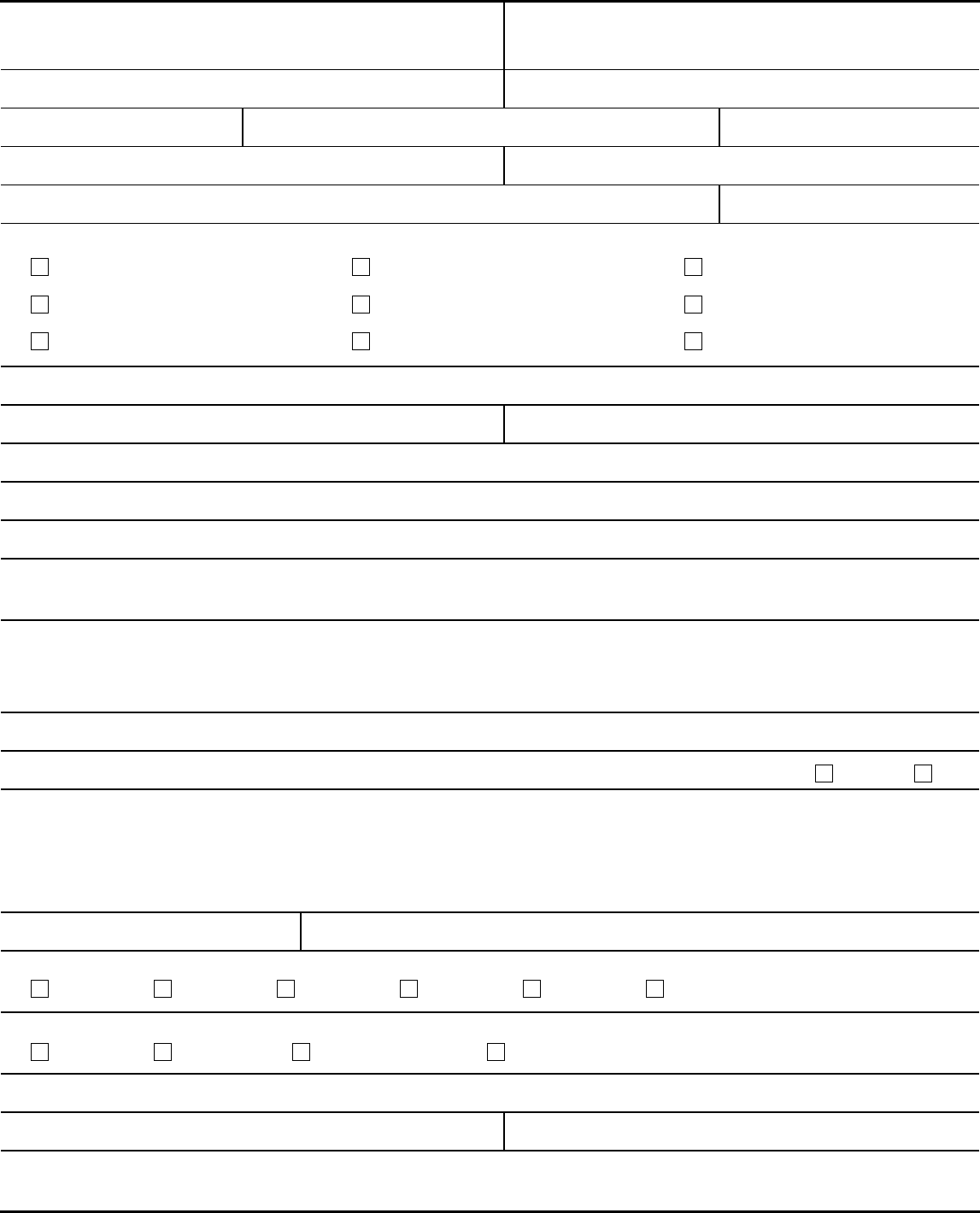

22. GENERAL CONDITION OF PRESSURE VESSEL

23. HAS INTERIOR OF SHELL BEEN PROTECTED AGAINST CORROSION?

23A. IF SO, DESCRIBE SAME

24. DOES VESSEL CONTAIN OIL?

24C. IF SO, TO WHAT EXTENT ARE QUANTITIES CONSIDERED SERIOUS?

25. WAS PITTING OR CORROSION APPARENT?

25A. IF SO, TO WHAT EXTENT?

26. DOES VESSEL SHOW SIGNS OF DISTORTION?

26A. IF SO, TO WHAT EXTENT?

27. HAS CORROSION INHIBITOR BEEN USED?

27A. IF SO, DESCRIBE SAME

28. CONDITION OF HEAT TRANSFER SURFACE

29. CONDITION OF TUBE SUPPORTS

30. SHELL (Hydrostatic) (Pneumatic) PRESSURE OF

31. DID PRESSURE VESSEL SHOW DEFECTS UNDER THIS PRESSURE?

31A. IF SO, WHERE AND TO WHAT EXTENT?

32. WAS TEST PRESSURE 1 1/2 TIMES THE MAXIMUM ALLOWABLE WORKING PRESSURE AS RATED BY THE MANUFACTURER?

32A. IF NOT, WHY WAS MAXIMUM PRESSURE NOT APPLIED?

33. RECOMMENDED MAXIMUM SAFE WORKING PRESSURE AS A RESULT OF THIS TEST

34. *PRESSURE RELIEF VALVES

35. ARE THESE VALUES ALSO DESIGNED FOR TEMPERATURE PROTECTION?

36. IF NOT, IS THERE ANY TEMPERATURE PROTECTION OR CONTROL?

36A. DESCRIBE SAME

24A. DOES VESSEL CONTAIN GREASE?24B. DOES VESSEL CONTAIN SCALE?

NO

YESNOYESNOYESNO

YES

NO

YESNO

LBS./SQ. IN. WAS APPLIED

LBS./SQ/ IN

NUMBERTYPESIZE

YESNO

YESNO

YES

NOYES

NO

YES

NO

YES

GSAFORM350PAGE 2(3-51)

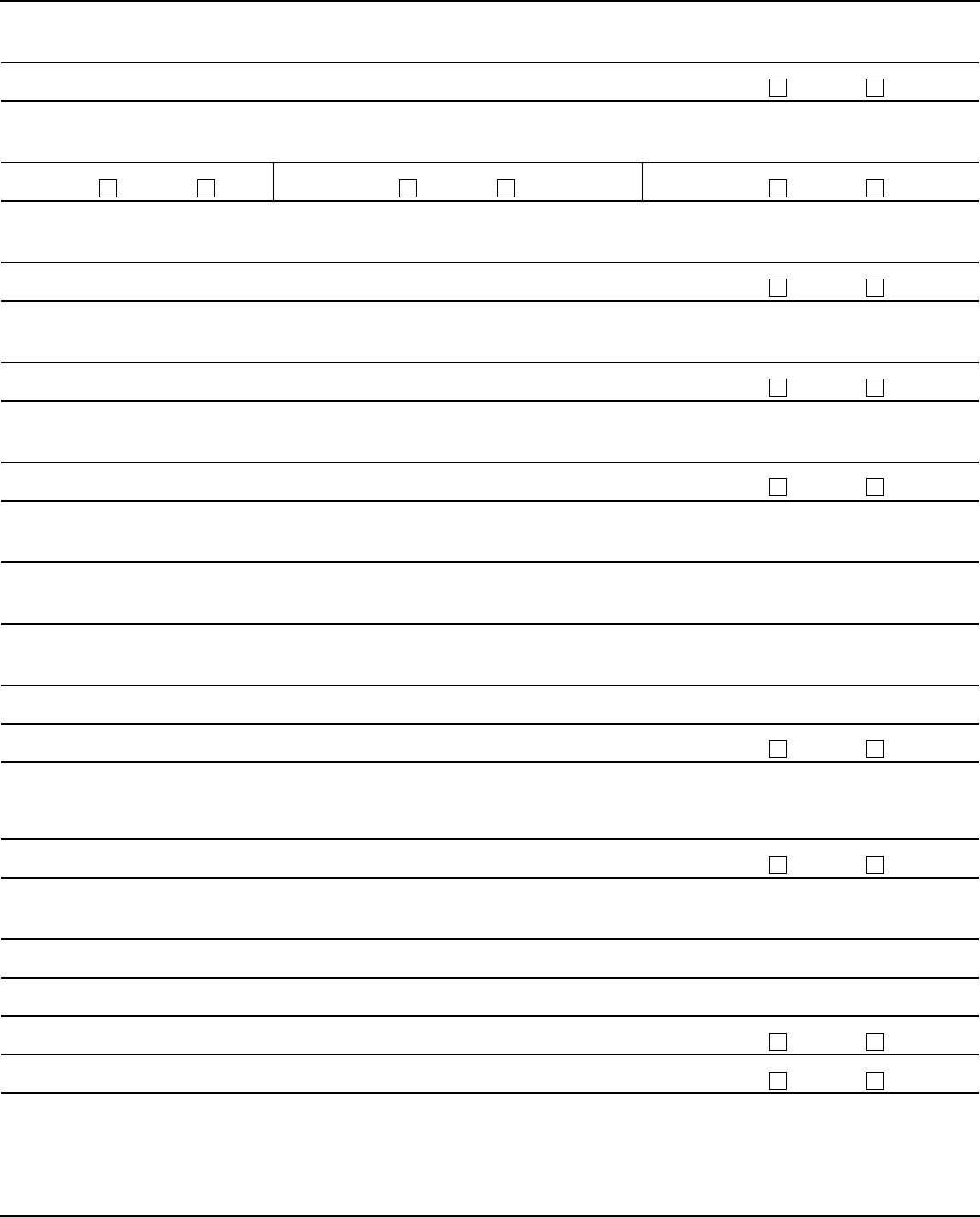

37. STATE CONDITION OF PRESSURE AND/OR TEMPERATURE RELIEF VALVES

38. DESCRIBE ANY OTHER CONTROLS AND STATE THEIR CONDITIONS

39. WERE RELIEF VALVES RESET?

39A. IF SO, FOR WHAT CONDITIONS?

40. CONDITION OF PRESSURE VESSEL GAUGES AND THERMOMETERS

42. WERE GAUGES AND THERMOMETERS CORRECTED OR RENEWED?

43. DOES VESSEL CONTAIN SAFETY PLUGS?

43A. IF SO, STATE CONDITION

44. WERE SAFETY PLUGS RENEWED?

45. CONDITION OF GAUGE GLASS, IF FITTED

46. CONDITION OF PIPE CONNECTIONS AND ATTACHMENTS

47. CONDITION OF HEAT TRANSFER HEADER MANIFOLD

48. WAS HEAT TRANSFER SYSTEM TESTED FOR TIGHTNESS?

48A. IF SO, DESCRIBE METHOD AND GIVE RESULTS

49. WHAT REPAIRS OR ALTERATIONS HAVE BEEN MADE SINCE LAST INSPECTION AND WHY WERE THEY MADE?

50. IF TOXIC GASES ARE USED IN PRESSURE VESSEL, HAS ADEQUATE PROVISION BEEN MADE TO PROTECT PERSONNEL?

51. HAS ADEQUATE PROVISION BEEN MADE FOR FIRE FIGHTING?

52. HOW DO PERSONNEL IN CHARGE OF THIS EQUIPMENT GRADE?

GIVE RECOMMENDATIONS REGARDING PERSONNEL

41. WHAT VARIATION IN PRESSURE AND/OR TEMPERATURE EXISTED BETWEEN PRESSURE VESSEL GAUGES AND THERMOMETERS AND

INSPECTOR'S TEST GAUGE AND THERMOMETER AT WORKING PRESSURE AND TEMPERATURE?

NO

YES

NO

YESNO

COMPETENTDOUBTFULINCOMPETENT

YES

NO

YES

NOYES

NO

YES

GSAFORM350PAGE 3(3-51)

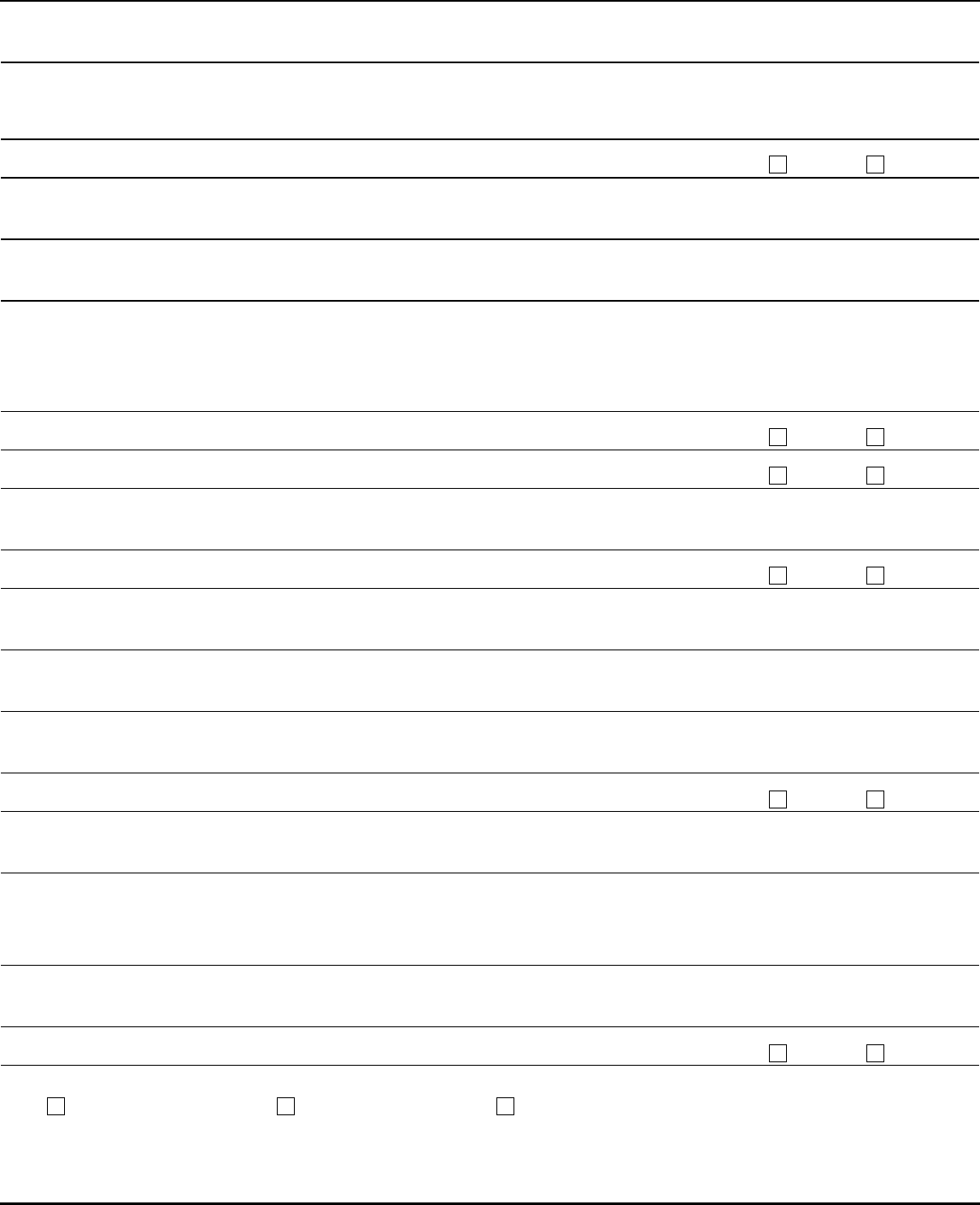

GSAFORM350PAGE 4(3-51)

53. IN YOUR OPINION IS THIS UNFIRED PRESSURE VESSEL IN A SAFE CONDITION TO BE OPERATED?

54. RECOMMENDATIONS AND REMARKS BY THE INSPECTOR (Include alterations, additions or repairs considered necessary)

54A. SIGNATURE OF INSPECTOR

54B. TITLE OF INSPECTOR

55. RECOMMENDATIONS AND REMARKS BY LOCAL OFFICER OR ENGINEER IN CHARGE

55A. SIGNATURE OF OFFICER IN CHARGE

55B. OFFICIAL TITLE OF OFFICER IN CHARGE

NOTE: Use additional sheets if necessary, to supplement the above remarks.

53A. IF ANSWER TO QUESTION 53 IS NO, THE INSPECTOR WILL NOTIFY THE CUSTODIAN, OR BUILDING SUPERINTENDENT, IMMEDIATELY

IN WRITING, NOT TO SUE SAME AND GIVE COMPLETE DETAILS TO REGIONAL OFFICE BY WIRE.

YESNO