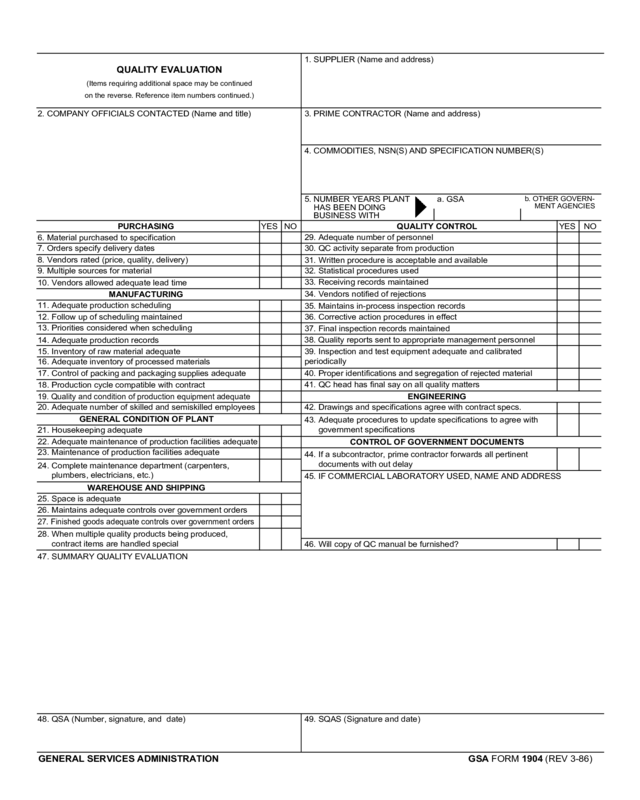

Fillable Printable Quality Evaluation Gsa Form 1904

Fillable Printable Quality Evaluation Gsa Form 1904

Quality Evaluation Gsa Form 1904

QUALITY EVALUATION

(Items requiring additional space may be continued

on the reverse. Reference item numbers continued.)

2. COMPANY OFFICIALS CONTACTED (Name and title)

PURCHASING

1. SUPPLIER (Name and address)

3. PRIME CONTRACTOR (Name and address)

4. COMMODITIES, NSN(S) AND SPECIFICATION NUMBER(S)

5. NUMBER YEARS PLANT

HAS BEEN DOING

BUSINESS WITH

a. GSA

b. OTHER GOVERN-

MENT AGENCIES

YES NO NOYES

MANUFACTURING

GENERAL CONDITION OF PLANT

WAREHOUSE AND SHIPPING

QUALITY CONTROL

CONTROL OF GOVERNMENT DOCUMENTS

GSA FORM 1904 (REV 3-86)GENERAL SERVICES ADMINISTRATION

29. Adequate number of personnel

30. QC activity separate from production

48. QSA (Number, signature, and date)

31. Written procedure is acceptable and available

32. Statistical procedures used

33. Receiving records maintained

34. Vendors notified of rejections

35. Maintains in-process inspection records

36. Corrective action procedures in effect

37. Final inspection records maintained

38. Quality reports sent to appropriate management personnel

39. Inspection and test equipment adequate and calibrated

periodically

40. Proper identifications and segregation of rejected material

41. QC head has final say on all quality matters

42. Drawings and specifications agree with contract specs.

43. Adequate procedures to update specifications to agree with

government specifications

44. If a subcontractor, prime contractor forwards all pertinent

documents with out delay

ENGINEERING

45. IF COMMERCIAL LABORATORY USED, NAME AND ADDRESS

46. Will copy of QC manual be furnished?

49. SQAS (Signature and date)

6. Material purchased to specification

7. Orders specify delivery dates

8. Vendors rated (price, quality, delivery)

9. Multiple sources for material

10. Vendors allowed adequate lead time

11. Adequate production scheduling

12. Follow up of scheduling maintained

13. Priorities considered when scheduling

14. Adequate production records

15. Inventory of raw material adequate

16. Adequate inventory of processed materials

17. Control of packing and packaging supplies adequate

18. Production cycle compatible with contract

19. Quality and condition of production equipment adequate

20. Adequate number of skilled and semiskilled employees

21. Housekeeping adequate

22. Adequate maintenance of production facilities adequate

23. Maintenance of production facilities adequate

24. Complete maintenance department (carpenters,

plumbers, electricians, etc.)

25. Space is adequate

26. Maintains adequate controls over government orders

27. Finished goods adequate controls over government orders

28. When multiple quality products being produced,

contract items are handled special

47. SUMMARY QUALITY EVALUATION