Fillable Printable Sample Electrical Installation Condition Report Form

Fillable Printable Sample Electrical Installation Condition Report Form

Sample Electrical Installation Condition Report Form

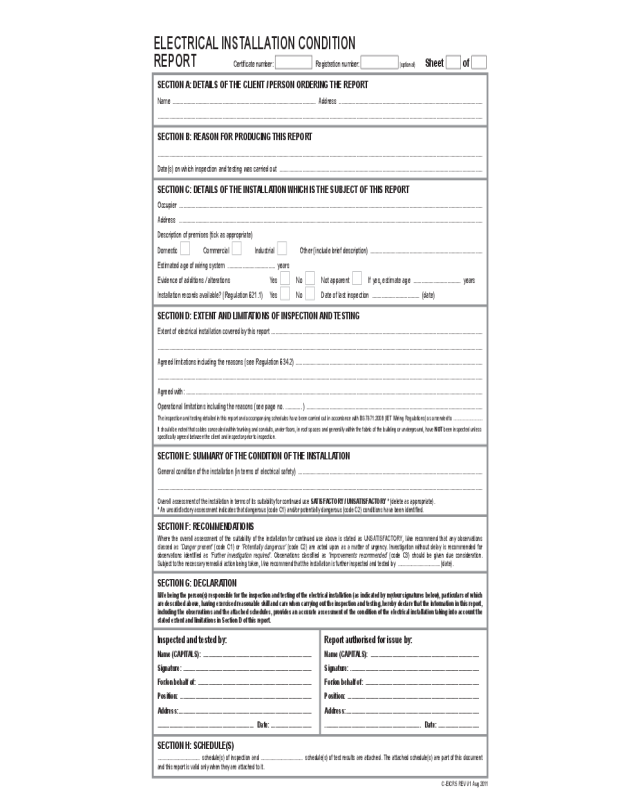

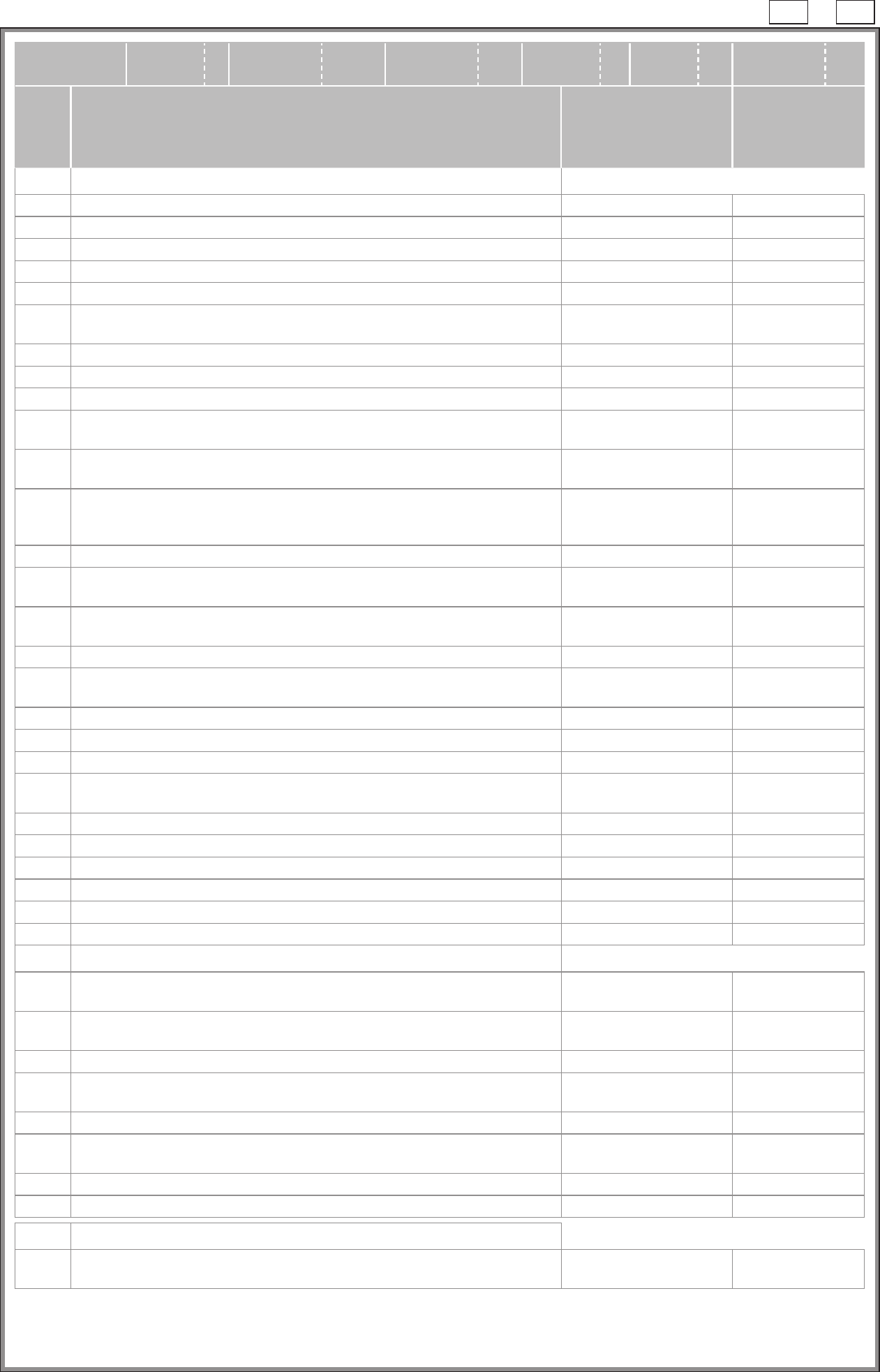

SECTION A: DETAIlS Of ThE ClIENT / pErSON OrDErINg ThE rEpOrT

Name .......................................................................................................... Address ..........................................................................................................

................................................................................................................................................................................................................................................

SECTION C: DETAIlS Of ThE INSTAllATION whICh IS ThE SubjECT Of ThIS rEpOrT

Occupier ................................................................................................................................................................................................................................

Address ................................................................................................................................................................................................................................

Description of premises (tick as appropriate)

Domestic Commercial Industrial Other (include brief description) ...................................................................................

Estimated age of wiring system ................................... years

Evidence of additions / alterations Yes

No Not apparent If yes, estimate age ................................... years

Installation records available? (Regulation 621.1) Yes

No Date of last inspection ................................... (date)

SECTION g: DEClArATION

I/we being the person(s) responsible for the inspection and testing of the electrical installation (as indicated by my/our signatures below), particulars of which

are described above, having exercised reasonable skill and care when carrying out the inspection and testing, hereby declare that the information in this report,

including the observations and the attached schedules, provides an accurate assessment of the condition of the electrical installation taking into account the

stated extent and limitations in Section D of this report.

Inspected and tested by:

Name (CApITAlS): ................................................................................

Signature: ...............................................................................................

for/on behalf of: ....................................................................................

position: .................................................................................................

Address: ..................................................................................................

....................................................................... Date: ..............................

SECTION b: rEASON fOr prODuCINg ThIS rEpOrT

................................................................................................................................................................................................................................................

Date(s) on which inspection and testing was carried out ......................................................................................................................................................

SECTION D: ExTENT AND lImITATIONS Of INSpECTION AND TESTINg

Extent of electrical installation covered by this report ............................................................................................................................................................

................................................................................................................................................................................................................................................

Agreed limitations including the reasons (see Regulation 634.2) ..........................................................................................................................................

................................................................................................................................................................................................................................................

Agreed with: ...........................................................................................................................................................................................................................

Operational limitations including the reasons (see page no. ............ ) ..................................................................................................................................

The inspection and testing detailed in this report and accompanying schedules have been carried out in accordance with BS 7671:2008 (IET Wiring Regulations) as amended to ............................

It should be noted that cables concealed within trunking and conduits, under oors, in roof spaces and generally within the fabric of the building or underground, have NOT been inspected unless

specically agreed between the client and inspector prior to inspection.

SECTION E: SummAry Of ThE CONDITION Of ThE INSTAllATION

General condition of the installation (in terms of electrical safety) ........................................................................................................................................

................................................................................................................................................................................................................................................

Overall assessment of the installation in terms of its suitability for continued use SATISfACTOry / uNSATISfACTOry * (delete as appropriate).

* An unsatisfactory assessment indicates that dangerous (code C1) and/or potentially dangerous (code C2) conditions have been identied.

SECTION f: rECOmmENDATIONS

Where the overall assessment of the suitability of the installation for continued use above is stated as UNSATISFACTORY, I/we recommend that any observations

classed as ‘Danger present’ (code C1) or ‘Potentially dangerous’ (code C2) are acted upon as a matter of urgency. Investigation without delay is recommended for

observations identied as ‘Further investigation required’. Observations classied as ‘Improvements recommended’ (code C3) should be given due consideration.

Subject to the necessary remedial action being taken, I/we recommend that the installation is further inspected and tested by ................................... (date).

report authorised for issue by:

Name (CApITAlS): ................................................................................

Signature: ...............................................................................................

for/on behalf of: ....................................................................................

position: .................................................................................................

Address: ..................................................................................................

....................................................................... Date: ..............................

SECTION h: SChEDulE(S)

................................... schedule(s) of inspection and ................................... schedule(s) of test results are attached. The attached schedule(s) are part of this document

and this report is valid only when they are attached to it.

C-EICR5 REV V1 Aug 2011

ElECTrICAl INSTAllATION CONDITION

rEpOrT Certicate number: Registration number: (optional) Sheet of

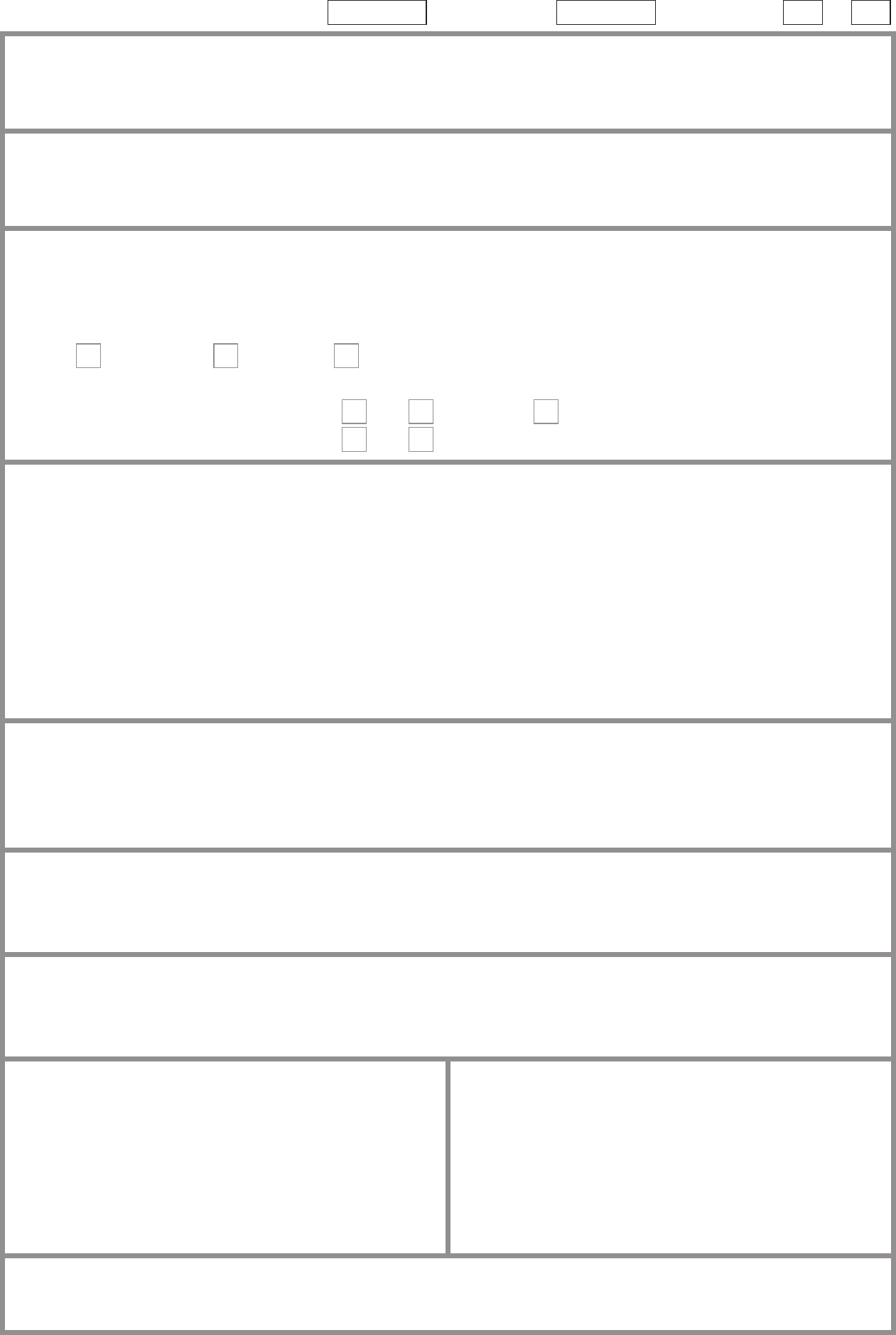

SECTION I: Supply ChArACTErISTICS AND EArThINg ArrANgEmENTS

Earthing arrangements Number and type of live conductors Nature and type of supply parameters Supply protective device

TN-C

TN-S

TN-C-S

TT

IT

a.c.

d.c.

1-phase, 2 wire

2-wire

2-phase, 3 wire

3-wire

3-phase, 3 wire

3-phase, 4 wire

Conrmation of supply polarity

Nominal voltage, U / U

o

(1)

.......................... V

Nominal frequency, f

(1)

............................. Hz

Prospective fault current, I

pf

(2)

................... kA

External loop impedance, Ze

(2)

.................. Ω

Note: (1) by enquiry. (2) by enquiry or measurement

BS (EN) ....................................

Type ..........................................

Rated current ......................... A

Other sources of supply (as detailed on attached schedule)

SECTION j: pArTICulArS Of INSTAllATION rEfErrED TO IN rEpOrT

means of earthing Details of Earth Electrode (where applicable)

Distributor’s facility

Installation earth

electrode

Type .......................................................................................................................................................................................

Location .................................................................................................................................................................................

Resistance to earth ............................................... Ω

main protective conductors

Earthing conductor Material ........................................... Csa ......................................... mm

2

Connection/continuity veried

Main protective bonding conductors

Material ........................................... Csa ......................................... mm

2

Connection/continuity veried

To incoming water service To incoming gas service To incoming oil service To structural steel

To lightning protection To other incoming service(s)

Specify ........................................................................................................

main switch / switch fuse / circuit breaker / rCD

Location ...............................................................

.............................................................................

BS (EN) ..............................................................

No. of poles .........................................................

Current rating ................................................... A

Fuse / device rating or setting ......................... A

Voltage rating ................................................... V

If rCD main switch

Rated residual operating current (I∆n) ............mA

Rated time delay ............................................. ms

Measured operating time (at I∆n) ................... ms

SECTION K: ObSErVATIONS

Referring to the attached schedules of inspection and test results, and subject to the limitations specied in the Extent and Limitations of Inspection

and testing section

No remedial action is required The following observations are made: (See below)

Observation(s)

Classication

code

further

investigation

required

(yES/NO)

One of the following codes, as appropriate, has been allocated to each of the observations made to indicate to the person(s) responsible for the

installation the degree of urgency of remedial action required.

C1 – Danger present. Risk of injury. Immediate remedial action required

C2 – Potentially dangerous. Urgent remedial action required

C3 – Improvement recommended

Use additional form if required

ElECTrICAl INSTAllATION CONDITION

rEpOrT Sheet of

C-EICR5 REV V1 Aug 2011

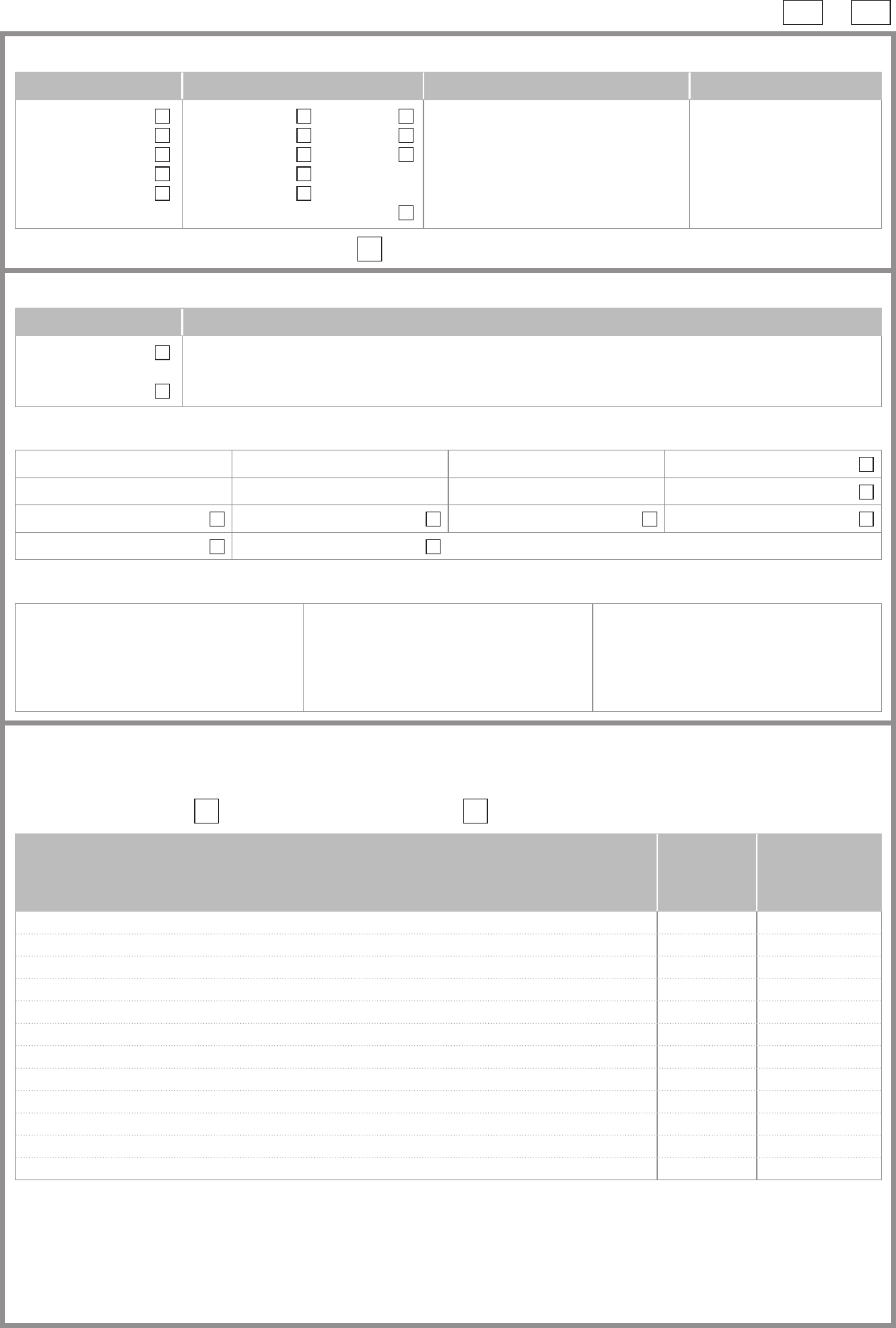

NOTE: This form is suitable for many types of smaller installations not exclusively domestic

OuTCOmES

Acceptable

condition

Unacceptable

condition

State

C1 or C2

Improvement

recommended

State

C3

Not veried

NV

Limitation

lim

Not applicable

N/A

Item

no

Description

Outcome

(Use codes above, provide additional

comment where appropriate.

C1, C2 and C3 coded items to be recorded

in Section K of the Condition Report)

further

investigation

required?

(YES / NO)

1.0 DISTrIbuTOr’S / Supply INTAKE EQuIpmENT

1.1 Service cable condition

1.2 Condition of service head

1.3 Condition of tails – distributor

1.4 Condition of tails – consumer

1.5 Condition of metering equipment

1.6 Condition of isolator (where present)

2.0 prESENCE Of ADEQuATE ArrANgEmENTS fOr SECONDAry Or

AlTErNATIVE SOurCES SuCh AS mICrOgENErATOrS (551.6; 551.7)

3.0 EArThINg / bONDINg ArrANgEmENTS (411.3; chap 54)

3.1 Presence and condition of distributor’s earthing arrangement (542.1.2.1; 542.1.2.2)

3.2 Presence and condition of earth electrode where applicable (542.1.2.3)

3.3 Provision of earthing / bonding labels at all appropriate locations (514.13.1)

3.4 Conrmation of earthing conductor size (542.3; 543.1.1)

3.5 Accessibility and condition of earthing conductor at MET (543.3.2)

3.6 Conrmation of main protective bonding conductor sizes (544.1)

3.7

Condition and accessibility of main protective bonding conductor connections

(543.3.2; 544.1.2)

3.8 Accessibility and condition of all protective bonding connections (543.3.2)

4.0 CONSumEr uNIT(S) / DISTrIbuTION bOArD(S)

4.1 Adequacy of working space / accessibility to consumer unit / distribution board

(132.12; 513.1)

4.2 Security of xing (134.1.1)

4.3 Condition of enclosure(s) in terms of IP rating etc (416.2)

4.4 Condition of enclosure(s) in terms of re rating etc (526.5)

4.5 Enclosure not damaged / deteriorated so as to impair safety (621.2 iii)

4.6 Presence of main linked switch (as required by 537.1.4)

4.7 Operation of main switch (functional check) (612.13.2)

4.8 Manual operation of circuit-breakers and RCDs to prove disconnection (612.13.2)

4.9 Correct identication of circuit details and protective devices (514.8.1; 514.9.1)

4.10 Presence of RCD quarterly test notice present at or near consumer unit / distribution

board (514.12.2)

4.11 Presence of non-standard (mixed) cable colour warning notice at or near consumer

unit / distribution board (514.14)

4.12 Presence of alternative supply warning notice at or near consumer unit / distribution

board (514.15)

4.13 Presence of other required labelling (please specify) (Section 514)

4.14 Examination of protective device(s) and base(s); correct type and rating (no signs of

unacceptable thermal damage, arcing or overheating) (421.1.3)

4.15 Single-pole protective devices in line conductor only (132.14.1; 530.3.2)

4.16 Protection against mechanical damage where cables enter consumer unit /

distribution board (522.8.1; 522.8.11)

4.17 Protection against electromagnetic effects where cables enter consumer unit /

distribution board / enclosures (521.5.1)

4.18 RCD(s) provided for fault protection – includes RCBOs (411.4.9; 411.5.2; 531.2)

4.19 RCD(s) provided for additional protection – includes RCBOs(411.3.3; 415.1)

C-EICR5 REV V1 Aug 2011

CONDITION rEpOrT INSpECTION SChEDulE Sheet of

Sheet of

C-EICR5 REV V1 Aug 2011

OuTCOmES

Acceptable

condition

Unacceptable

condition

State

C1 or C2

Improvement

recommended

State

C3

Not veried

NV

Limitation

lim

Not applicable

N/A

Item

no

Description

Outcome

(Use codes above, provide additional

comment where appropriate.

C1, C2 and C3 coded items to be recorded

in Section K of the Condition Report)

further

investigation

required?

(YES / NO)

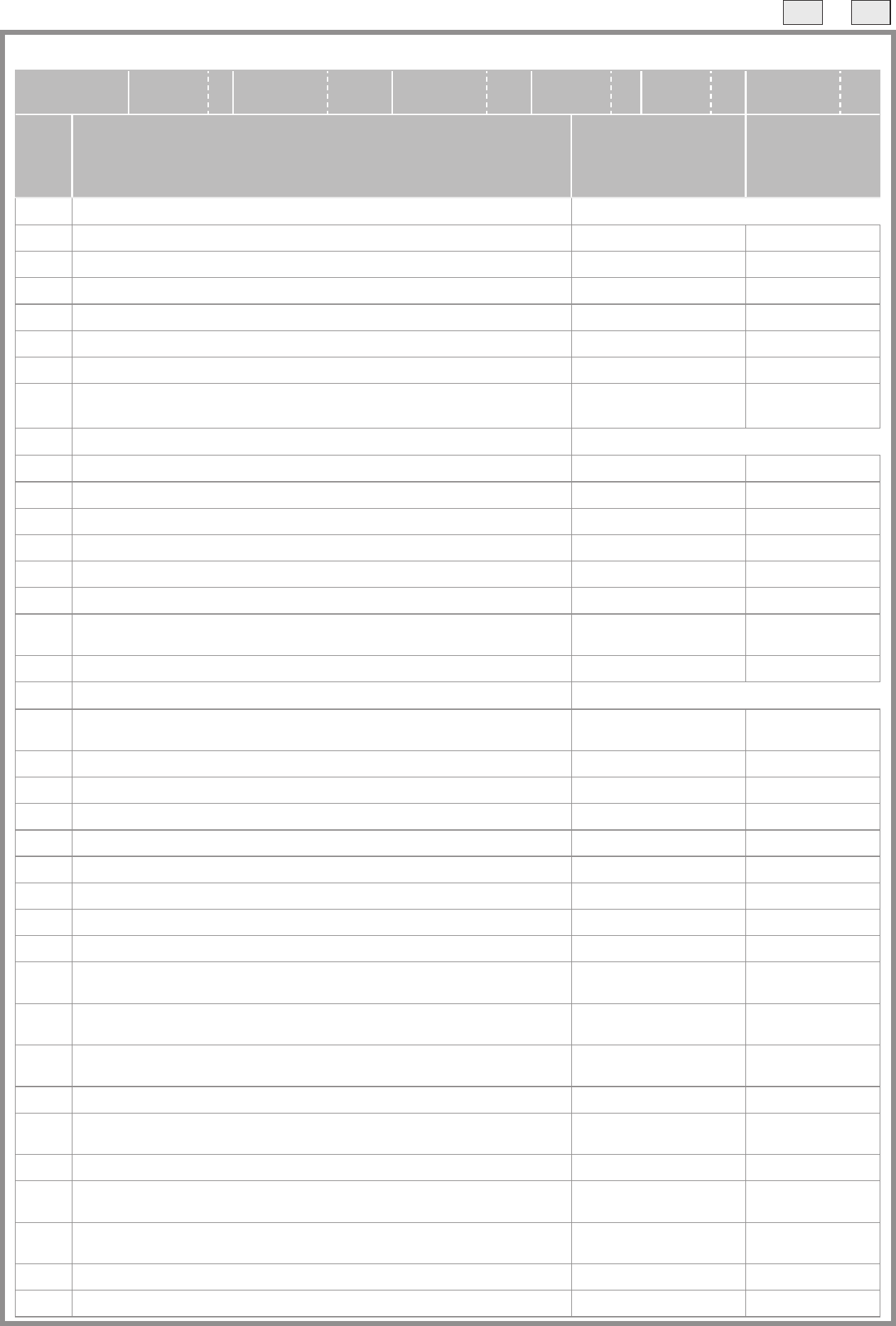

5.0 fINAl CIrCuITS

5.1 Identication of conductors (514.3.1)

5.2 Cables correctly supported throughout their run (522.8.5)

5.3 Condition of insulation of live parts (416.1)

5.4 Non-sheathed cables protected by enclosure in conduit, duct or trunking (521.10.1)

• To include the integrity of conduit and trunking systems (metallic and plastic)

5.5 Adequacy of cables for current-carrying capacity with regard for the type and nature

of installation (Section 523)

5.6 Co-ordination between conductors and overload protective devices (433.1; 533.2.1)

5.7 Adequacy of protective devices: type and rated current for fault protection (411.3)

5.8 Presence and adequacy of circuit protective conductors (411.3.1.1; Section 543.1)

5.9 Wiring system(s) appropriate for the type and nature of the installation and external

inuences (Section 522)

5.10

Concealed cables installed in prescribed zones (see Section D: Extent and limitations)

(522.6.101)

5.11 Concealed cables incorporating earthed armour or sheath, or run within earthed

wiring system, or otherwise protected against mechanical damage from nails, screws

and the like (see Section D: Extent and limitations) (522.6.101; 522.6.103)

5.12 Provision of additional protection by RCD not exceeding 30 mA:

• For all socket-outlets of rating 20 A or less provided for use by ordinary persons

unless an exception is permitted (411.3.3)

• For supply to mobile equipment not exceeding 32 A rating for use outdoors

(411.3.3)

• For cables concealed in walls or partitions (522.6.102; 522.6.103)

5.13 Provision of re barriers, sealing arrangements and protection against thermal effects

(Section 527)

5.14 Band II cables segregated / separated from Band I cables (528.1)

5.15 Cables segregated / separated from communications cabling (528.2)

5.16 Cables segregated / separated from non-electrical services (528.3)

5.17

Termination of cables at enclosures – indicate extent of sampling in Section D of the

report (Section 526)

• Connections soundly made and under no undue strain (526.6)

• No basic insulation of a conductor visible outside enclosure (526.8)

• Connections of live conductors adequately enclosed (526.5)

• Adequately connected at point of entry to enclosure (glands, bushes, etc.) (522.8.5)

5.18 Condition of accessories including socket-outlets, switches and joint boxes (621.2(iii))

5.19 Suitability of accessories for external inuences (512.2)

6.0 lOCATION(S) CONTAININg A bATh Or ShOwEr

6.1 Additional protection for all low voltage (LV) circuits by RCD not exceeding 30 mA

(701.411.3.3)

6.2 Where used as a protective measure, requirements for SELV or PELV met

(701.414.4.5)

6.3 Shaver sockets comply with BS EN 61558-2-5 formerly BS 3535 (701.512.3)

6.4 Presence of supplementary bonding conductors, unless not required by

BS 7671:2008 (701.415.2)

6.5 Low voltage (e.g. 230 volts) socket-outlets sited at least 3 m from zone 1 (701.512.3)

6.6 Suitability of equipment for external inuences for installed location in terms of IP

rating (701.512.2)

6.7 Suitability of equipment for installation in a particular zone (701.512.3)

6.8 Suitability of current-using equipment for a particular position within the location (701.55)

7.0 OThEr pArT 7 SpECIAl INSTAllATIONS Or lOCATIONS

7.1 List all other special installations or locations present, if any (record separately the

results of particular inspections applied).

Tested by:

Name (CApITAlS) .......................................................... Signature .......................................................... Date .....................................

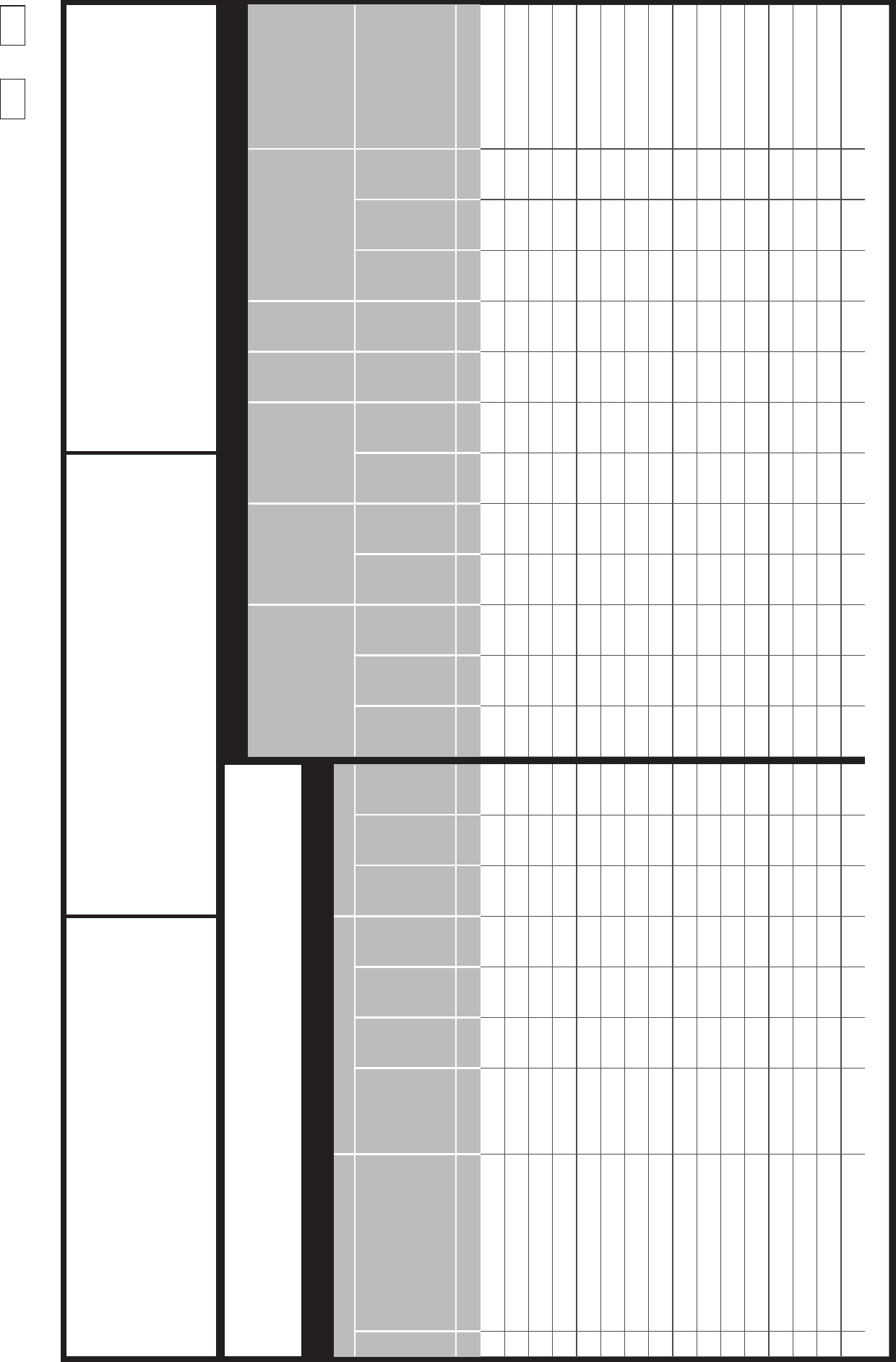

Schedule of teSt reSultS Sheet of

DB Reference no. .......................................................................................

Location ......................................................................................................

Zs at DB (Ω) ...............................................................................................

I

pf

at DB (kA) ...............................................................................................

Correct polarity of supply conrmed YES / NO

Phase sequence conrmed (where appropriate)

Details of circuits and/or installed equipment vulnerable to damage when testing

.................................................................................................................................

.................................................................................................................................

.................................................................................................................................

.................................................................................................................................

.................................................................................................................................

Details of test instruments used (state serial and/or asset numbers)

Continuity ......................................................................................................

Insulation resistance .....................................................................................

Earth fault loop impedance ...........................................................................

RCD ..............................................................................................................

Earth electrode resistance ............................................................................

tested by:

Name (capitalS)...............................................................................................................................

Signature........................................................................ date ..........................................................

test results

Ring nal circuit

continuity (Ω)

Continuity (Ω)

(R

1

+ R

2

) or R

2

Insulation

resistance

(MΩ)

Polarity

Z

s

(Ω)

RCD

(ms)

Remarks

(continue on a

separate sheet if

necessary)

circuit details

Overcurrent device Conductor details

Circuit number

Circuit description

BS (EN)

Type

Rating (A)

Breaking

capacity (kA)

Reference

method

Live (mm

2

)

cpc (mm

2

)

r

1

(line)

r

n

(neutral)

r

2

(cpc)

(R

1

+ R

2

) *

R

2

Live – Live

Live – E

Ω

@I

∆

n

@5I

∆

n

Test button

operation

A B C D E F G H I J K L M N O P Q R S T U V

* Where there are no spurs connected to a ring nal circuit this value is also the (R

1

+ R

2

) of the circuit.

C-STR REV Aug 2011 V1

CONDITION rEpOrT

guIDANCE fOr rECIpIENTS

(to be appended to the report)

This report is an important and valuable document which should be retained for future reference.

1 The purpose of this Condition Report is to conrm, so far as reasonably practicable, whether or not the electrical

installation is in a satisfactory condition for continued service (see Section E). The Report should identify any damage,

deterioration, defects and/or conditions which may give rise to danger (see Section M).

2 The person ordering the Report should have received the original Report and the inspector should have retained a

duplicate.

3 The original Report should be retained in a safe place and be made available to any person inspecting or undertaking

work on the electrical installation in the future. If the property is vacated, this Report will provide the new owner/occupier

with details of the condition of the electrical installation at the time the Report was issued.

4 Where the installation incorporates residual current devices (RCDs) there should be a notice at or near the devices

stating that they should be tested regularly. for safety reasons it is important that these instructions are followed.

5 Section D (Extent and Limitations) should identify fully the extent of the installation covered by this Report and any

limitations on the inspection and testing. The inspector should have agreed these aspects with the person ordering the

Report and with other interested parties (licensing authority, insurance company, mortgage provider and the like) before

the inspection was carried out.

6 Some operational limitations such as inability to gain access to parts of the installation or an item of equipment may have

been encountered during the inspection. The inspector should have noted these in Section D.

7 For items classied in Section K as C1 (‘Danger present’),

the safety of those using the installation is at risk, and it

is recommended that a competent person undertakes the necessary remedial work immediately.

8 For items classied in Section K as C2 (‘Potentially dangerous’),

the safety of those using the installation may be at

risk, and it is recommended that a competent person undertakes the necessary remedial work as a matter of urgency.

9 Where it has been stated in Section K that an observation requires further investigation, the inspection has revealed

an apparent deciency which could not, due to the extent or limitations of this inspection, be fully identied. Such

observations should be investigated as soon as possible. A further examination of the installation will be necessary, to

determine the nature and extent of the apparent deciency (see Section F).

10 For safety reasons, the electrical installation should be re-inspected at appropriate intervals by a competent person. The

recommended date by which the next inspection is due is stated in Section F of the Report under ‘Recommendations’

and on a label near to the consumer unit / distribution board.

CONDITION rEpOrT

guIDANCE fOr ThE INSpECTOr

This report is an important and valuable document which should be retained for future reference.

1 Section 1. Where inadequacies in the distributor’s equipment are present, the inspector should advise the person

ordering the work to inform the appropriate authority.

2 Older installations designed prior to BS 7671:2008 are unlikely to have been provided with RCDs for additional protection.

The absence of such protection should, as a minimum, be given a code C3 classication (item 5.12).

3 This schedule is not exhaustive.

4 Numbers in brackets are Regulation references to specied requirements.