Fillable Printable Underground Installation Form

Fillable Printable Underground Installation Form

Underground Installation Form

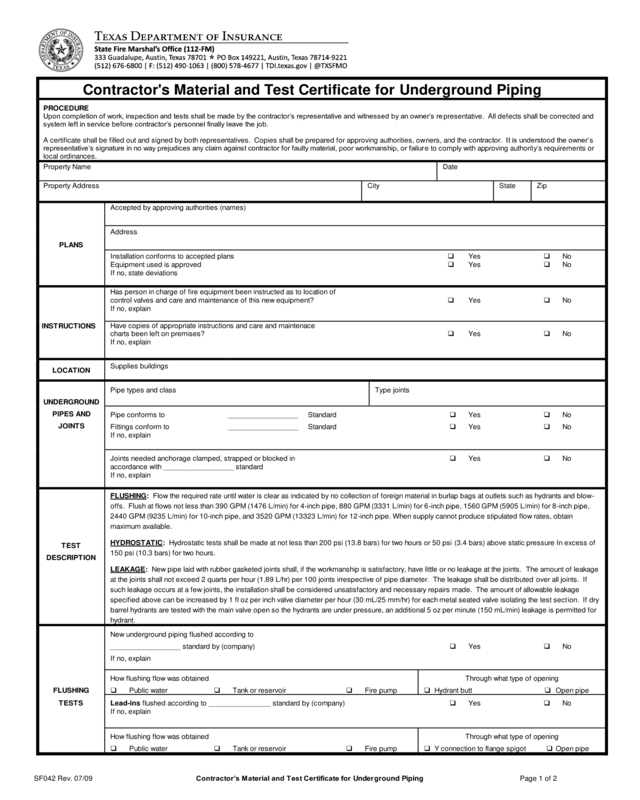

Contractor's Material and Test Certificate for Underground Piping

PROCEDURE

Upon completion of work, inspection and tests shall be made by the contractor’s representative and witnessed by an owner’s re presentative. All defects shall be corrected and

system left in service before contractor’s personnel finally leave the job.

A certificate shall be filled out and signed by both representatives. Copies shall be prepared for approving authorities, owners, and the contractor. It is understood the owner’s

representative’s signature in no way prejudices any claim against contractor for faulty material, poor workmanship, or failure to comply with approving authority’s requirements or

local ordinances.

Property Name

Date

Property Address

City

State

Zip

PLANS

Accepted by approving authorities (names)

Address

Installation conforms to accepted plans Yes No

Equipment used is approved

Yes

No

If no, state deviations

INST RUCT IONS

Has person in charge of fire equipment been instructed as to location of

control valves and care and maintenance of this new equipment? Yes No

If no, explain

Have copies of appropriate instructions and care and maintenace

charts been left on premises?

Yes

No

If no, explain

LOCAT ION

Supplies buildings

UNDERGROUND

PIPES AND

JOINT S

Pipe types and class

Type joints

Pipe conforms to _________________ Standard

Yes

No

Fittings conform to _________________ Standard

Yes

No

If no, explain

Joints needed anchorage clamped, strapped or blocked in

Yes

No

accordance with _________________ standard

If no, explain

T EST

DESCRIPT ION

FLUSHING: Flow the required rate until water is clear as indicated by no collection of foreign material in burlap bags at outlets such as hydrants and blow-

offs. Flush at flows not less than 390 GPM (1476 L/min) for 4-inch pipe, 880 GPM (3331 L/min) for 6-inch pipe, 1560 GPM (5905 L/min) for 8-inch pipe,

2440 GPM (9235 L/min) for 10-inch pipe, and 3520 GPM (13323 L/min) for 12-inch pipe. When supply cannot produce stipulated flow rates, obtain

maximum available.

HYDROST AT IC: Hydrostatic tests shall be made at not less than 200 psi (13.8 bars) for two hours or 50 psi (3.4 bars) above static pressure In excess of

150 psi (10.3 bars) for two hours.

LEAKAGE: New pipe laid with rubber gasketed joints shall, if the workmanship is satisfactory, have little or no leakage at the joints. The amount of leakage

at the joints shall not exceed 2 quarts per hour (1.89 L/hr) per 100 joints irrespective of pipe diameter. The leakage shall be distributed over all joints. If

such leakage occurs at a few joints, the installation shall be considered unsatisfactory and necessary repairs made. The amount of allowable leakage

specified above can be increased by 1 fl oz per inch valve diameter per hour (30 mL/25 mm/hr) for each metal seated valve isolating the test section. If dry

barrel hydrants are tested with the main valve open so the hydrants are under pressure, an additional 5 oz per minute (150 mL/min) leakage is permitted for

hydrant.

FLUSHING

T EST S

New underground piping flushed according to

_________________ standard by (company)

Yes

No

If no, explain

How flushing flow was obtained

Public water

Tank or reservoir

Fire pump

Through what type of opening

Hydrant butt

Open pipe

Lead-ins flushed according to _______________ standard by (company) Yes No

If no, explain

How flushing flow was obtained

Public water

Tank or reservoir

Fire pump

Through what type of opening

Y connection to flange spigot

Open pipe

SF042 Rev. 07/09 Contractor’s M aterial and T est Certificate for Underground Piping Page 1 of 2

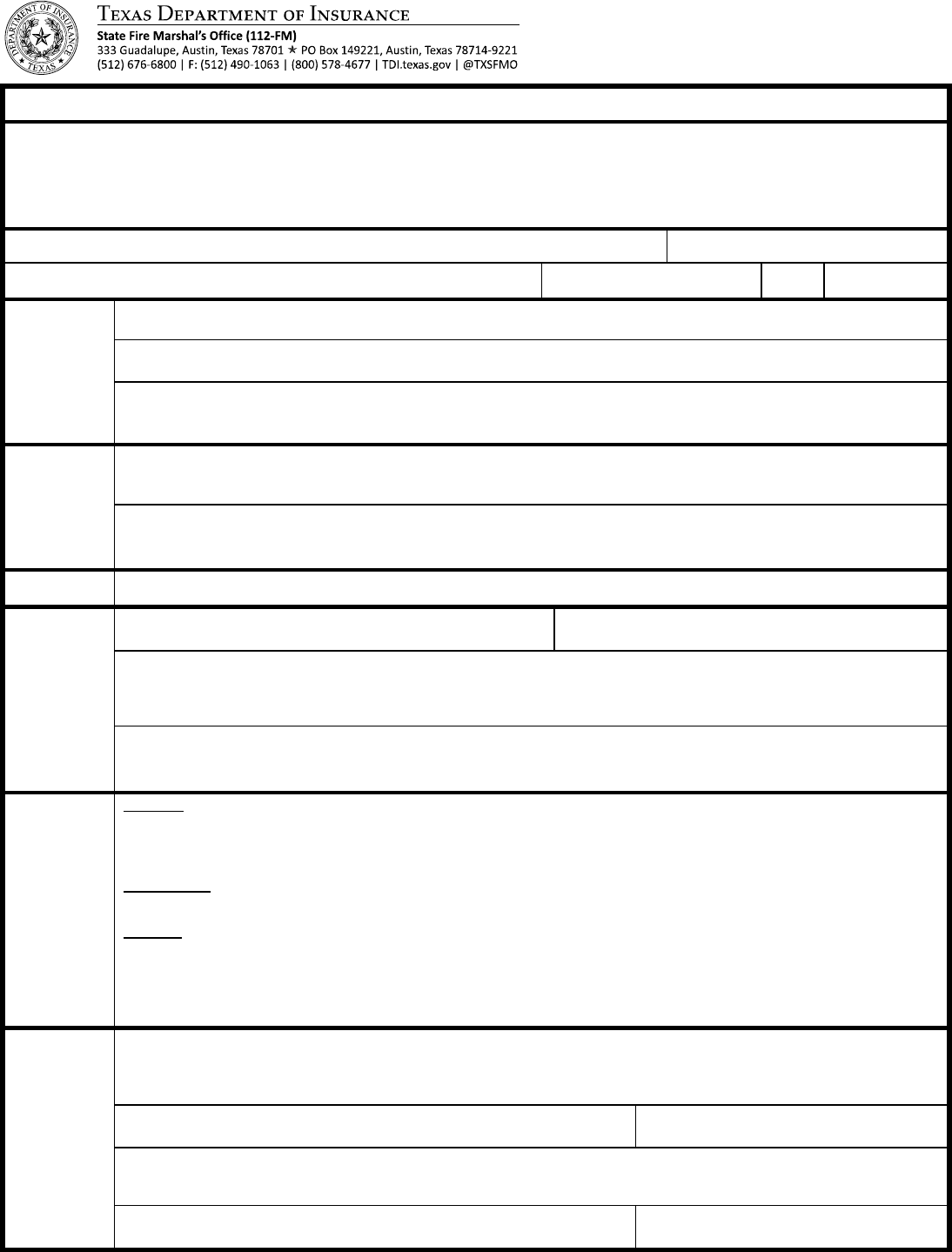

HYDROST AT IC

T EST

All new underground piping hydrostatically tested at

psi for hours

Joints covered

Yes

No

LEAKAGE

T EST

Total amount of leakage measured

gallons hours

Allowable leakage

gallons hours

HYDRANT S

Number installed

Type and make

All operate satisfactorily

Yes

No

CONT ROL

VALVES

Water control valves left wide open Yes No

If no, state reason

Hose threads of fire department connections and hydrants interchangeable with those of

the fire department answering alarm Yes No

REMARKS

Date left in service ________________________________ ________________________________________________________________ ________

________________________________________________________________________________________________ ________________________

________________________________________________________________________________________________ ________________________

Signature

Name of installing contractor

C of R No. SCR-

Contractor’s Address

City

State

Zip

Tests witnessed by

For property owner (signed) Title Date

For Installing contractor (signed) Title Date

Additional explanation and notes

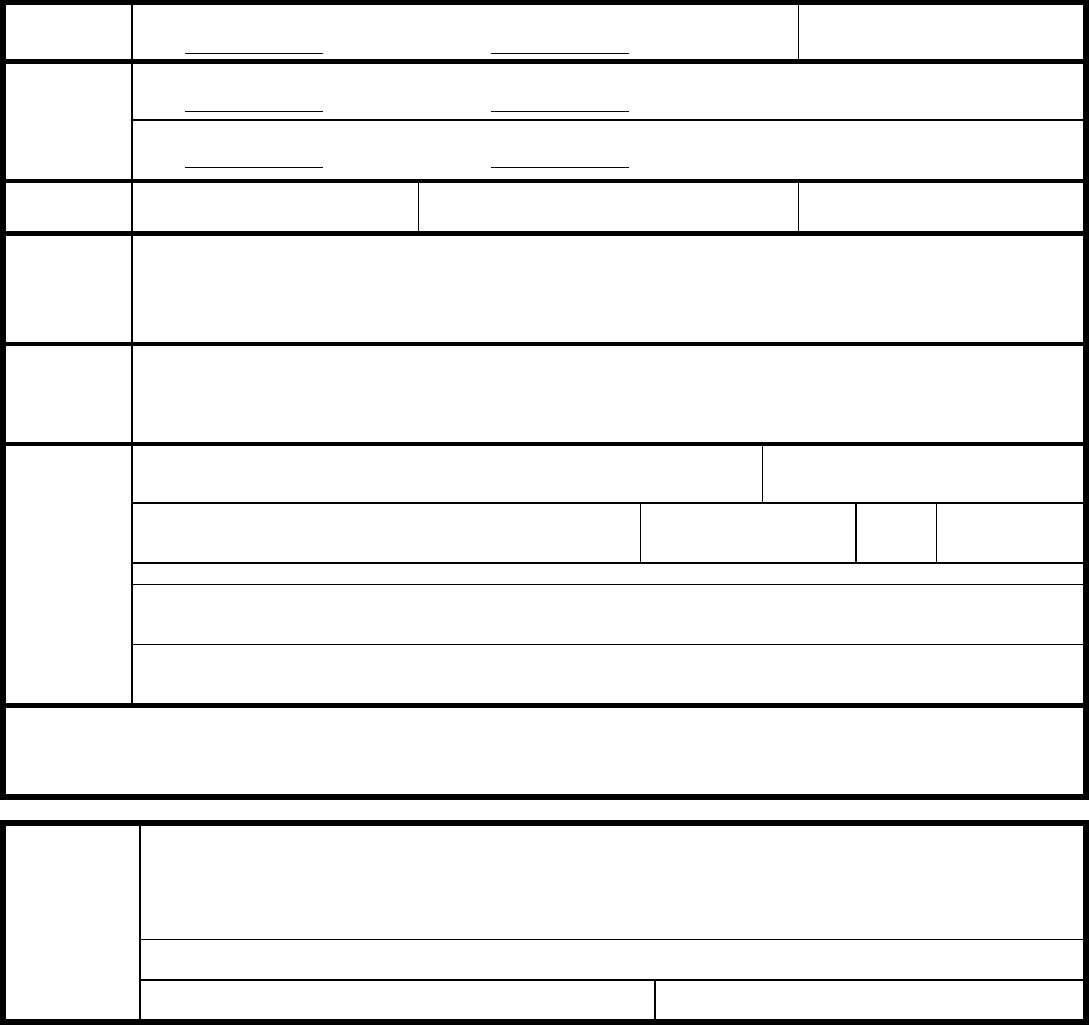

RME

I certify that the information herein is true and that this portion of the sprinkler system was installed in

accordance with Chapter 6003, Texas Insurance Code and the rules and standards adopted by the State Fire

Marshal’s Office.

Responsible Managing Employee (signature)

CERT IFICAT ION

Responsible Managing Employee (print or type name)

RME License Number

Date

DIST RIBUT ION: Original COPY 1 Posted at site or give to owner COPY 2 for the installing firm in file accessible to SFMO

COPY 3 for local approving authority within 10 days after completion

SF042 Rev. 07/09 Contractor’s M aterial and T est Certificate for Underground Piping Page 2 of 2