Fillable Printable Method Statement for Excavations

Fillable Printable Method Statement for Excavations

Method Statement for Excavations

A P R A C T I C A L G U I D E F O R T H E S M A L L E R C O N T R A C T O R

Method statement for excavations:

(a) strip foundations

(b) storm and sewerage to connect into existing manholes

Site Details

Contractor: The name and contact details of the contractor.

Project name and site address: Insert relevant details.

Site manager: Name, telephone number and email address.

Transfer of information from client/contractor to groundworks sub-contractor

• The site investigation will establish the engineering properties of the ground on which the

structure will be founded and provide details on bearing capacity. This information will be

communicated to the groundworks sub-contractor.

• If the site investigation identifies any contamination of the ground from previous industrial uses,

details of this will be given to the groundworks sub-contractor.

• Provide utility services drawings showing the location of any buried services.

• Where work has to be undertaken close by or beneath overhead lines, enquires will be made

with the line operator to establish whether the line can be made dead or diverted. Where

lines remain live ensure that plant is selected or modified so that it cannot reach the lines.

Ground works sub-contractor to comply with guidance note GS 6 ‘Avoidance of danger from

overhead power lines’.

A P R A C T I C A L G U I D E F O R T H E S M A L L E R C O N T R A C T O R

Attendances

Prior to any work taking place on site the client / contractor shall: -

• Use cable detection tools to accurately identify service locations on the ground and mark

same.

• Ensure that vehicle routes are carefully planned so that plant does not have to approach

close to the edge of the excavation. These routes need to be clearly marked i.e. baulks of

timber and/or fencing.

• Consider site access from the public road onto and around the site before vehicles arrive

on site, taking into account the site traffic management plan, the designated work area for

delivery vehicles and the storage area for materials. Clearly identify and communicate this

information to the groundworks sub-contractor.

• Make welfare facilities available to the groundworks sub-contractor.

Work activity

Pre-start checks: The pre-start checks must cover the following areas: -

availability of plant and equipment to be used; ground conditions; proximity hazards and welfare

facilities. Ensure the excavation area has been checked for overhead and underground services

prior to the commencement of work.

Description of the contract: Excavation and casting of strip foundations (600mm x 1.5m deep

excavation). Construction of storm and foul sewers (12m long) falling from a depth of 1.2m to

2.0m and connecting them into existing storm and foul manholes (information taken from working

drawings).

A P R A C T I C A L G U I D E F O R T H E S M A L L E R C O N T R A C T O R

(a) Sequence of work for strip foundation:

• On this particular site the average depth of excavation is 1.5m. It has been identified that

the ground conditions will allow for the trench sides to stand vertically without the use of

shutters. Strip foundations are to be excavated and concrete foundations poured on the

same day.

• No operatives are to enter excavation. The concrete will be poured directly into the

excavation and moved using rakes without the workers having to enter the excavation.

• The area to be excavated will be clearly marked on the surface using lime.

• Physical barriers will be erected around the excavation where appropriate.

• The groundworks sub-contractor will liaise with the client/contractor to ensure that any

live services on the site have been identified and clearly marked. Where necessary hand-

digging measures will be used to expose existing services.

• A 360 deg excavator will be used to dig a 600mm wide by approximately 1.5m deep

excavation.

• The material from the excavation will be loaded into a dumper and tipped away from

the working area so it does not apply a surcharge to the side of the excavation.

• The dumper will be fitted with roll-over protection and the driver must wear the seat belt.

No edge tipping is to take place.

• A banksman will be used to assist in the safe operation of the plant and to observe the

area being excavated to ensure there are no undiscovered services.

• Loose soil from both the base and the sides of the trench is to be removed prior to

placing concrete using the excavator.

A P R A C T I C A L G U I D E F O R T H E S M A L L E R C O N T R A C T O R

• Formation level to be inspected and passed. The excavation is to be filled with concrete

to the required level as set out using a laser.

• Ready mixed concrete will be used. Where the concrete cannot be poured directly into

the excavation via the chutes on the concrete lorry, the concrete will be placed in the

clean excavator bucket which will then place the concrete in the strip foundations.

(b) Sequence of work for excavations to lay storm and foul sewers and to connect into

existing manholes:

• A drag box (size 4.0m long by 2.0m high) will be selected to provide support to the sides

of the excavation as battering back the excavation is not an option on this site. A 360

deg 15tonne excavator is to be used in conjunction with the drag box.

• There are no significant groundwater problems anticipated on this site but if ingress of

water occurs during any time the excavation is open, it will be removed by a pump.

• A banksman is to be used to assist in the safe operation of the plant and to observe the

area being excavated to ensure there are no undiscovered services.

• Work will commence at the 1.2m deep end. A 360 deg excavator will be used to

excavate the trench to the recommended width (1.2m), pipe alignment and invert. The

drag box will be lowered into the pre-dug trench using the excavator.

• Excavated material will be stock piled away from the excavation using a dumper.

• Edge protection will be either connected to the drag box or free standing.

• Operatives must never use an unsupported section of the trench to gain access. Access

to the excavation will be by means for a secured ladder which extends 1m above the

step off level.

A P R A C T I C A L G U I D E F O R T H E S M A L L E R C O N T R A C T O R

• The sewer pipes are to be bedded on pea gravel (granular material), minimum depth

150mm.

• The trench will be progressed by digging ahead of the drag box and the excavator

dragging the box forward by pulling on the leading strut. Workers must work from within

the confines of the protected area i.e. inside the drag box to lay the sewers.

• Before operatives enter the foul manhole to connect incoming pipe, they must use a gas

tester to check the atmosphere to identity whether there is a risk of oxygen deficiency,

toxic gas, fire or explosion.

• If flammable or toxic gases are present they need to be purged from the manhole and

the atmosphere checked to ensure that purging has been effective.

• The drag box will be carefully removed by lifting and dragging the front strut when

operatives are well clear.

• The pipe surround (pea gravel over the pipe to a depth of 150mm) will be placed as

soon as the pipes have been laid, jointed and inspected. Selected backfill from the

trench excavation which is free from stones larger than 40mm and vegetable matter

will be used to complete the backfilling of the trench. Mechanical compaction is to be

avoided until the fill is at least 450mm above the pipe-work.

• It is the responsibility of the groundworks foreman to check the safety of the excavation:

1. at the start of the shift;

2. after any event likely to have affected the strength or stability of the excavation; and

3. after any material unintentionally falls or is dislodged.

• If excavation work lasts longer than seven days an inspection record is to be completed

by the foreman.

Plant details: The foreman will inspect the through examination certificate for the excavator

and the inspection report on the dumper.

A P R A C T I C A L G U I D E F O R T H E S M A L L E R C O N T R A C T O R

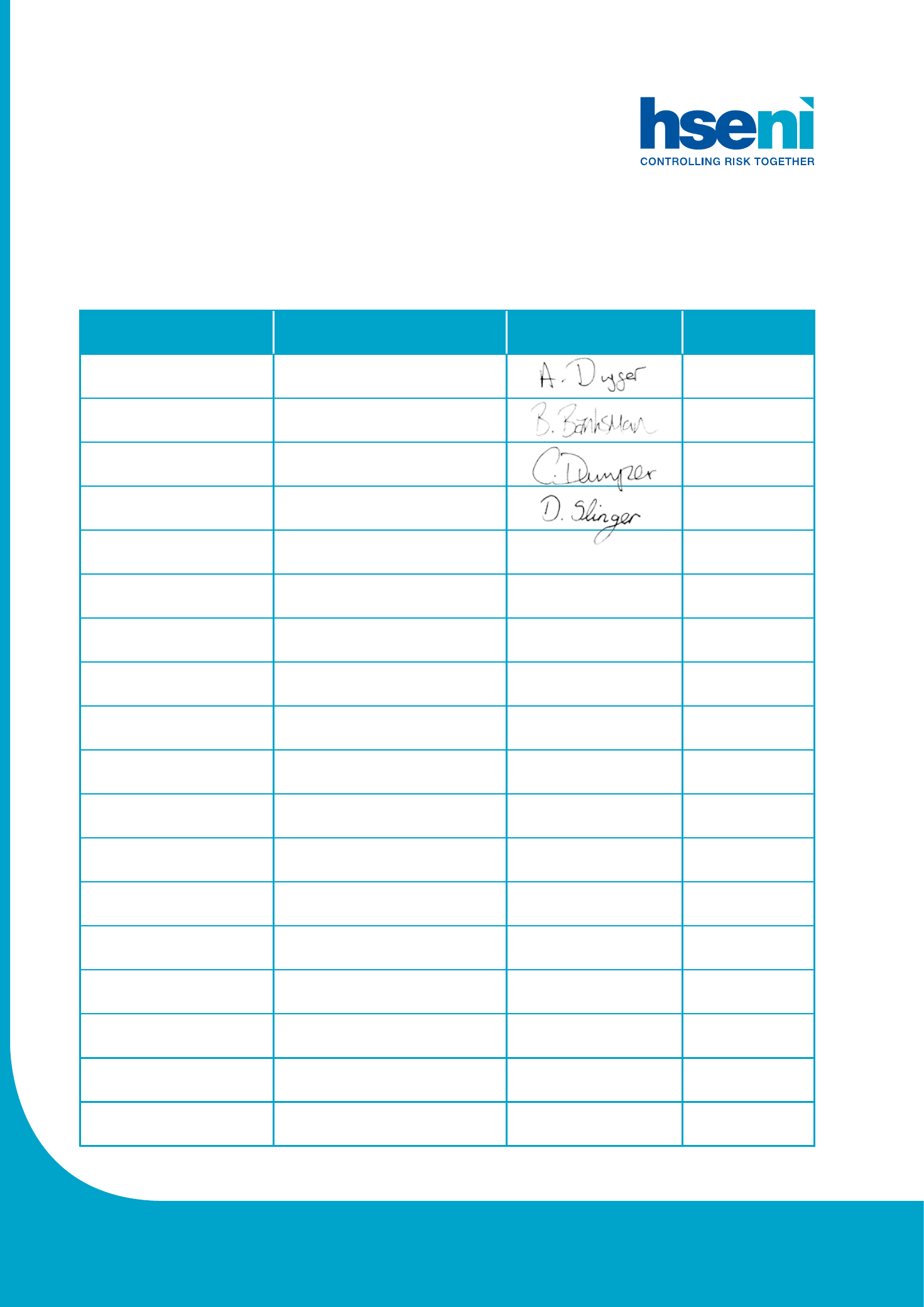

Personnel

Foreman: The foreman, (Name of Foreman) will identify himself to the site management on arrival

at site.

Banksman, excavator driver and dumper driver: The banksman and driver’s names are:

Training: All operatives will be fully trained and copies of training certificates for the following

will be available for inspection: slinger/signaller/banksmen; first aider; excavator driver; dumper

driveruse of gas monitoring equipment and use of cable locating equipment. Operatives /

supervisors who require access to sewers must complete confined space traning.

Other site operations / third parties: where co-operation and co-ordination with other site

operations / third parties is required this must be stated.

Health and safety management and control measures

Personal protective equipment: All operatives will wear the following: safety wellington boots whilst

working with concrete, safety helmet, high visibility vest and gloves.

Site rules: All operatives will be informed (via a site induction / toolbox talk) of and expected to

comply with the contractor’s site rules.

Specific site hazards: Any specific site hazards will be identified and dealt with prior to any

excavation work.

Access to the work area: The provision of a safe means of access to the work area is the

responsibility of the contractor / client.

A P R A C T I C A L G U I D E F O R T H E S M A L L E R C O N T R A C T O R

Falls into excavation: The groundworks sub-contractor must provide and maintain fencing to

prevent operatives from falling into the excavation where required.

Welfare facilities: The contractor / client must provide access to the welfare facilities.

Amendments and additional information

Amendments to the method statement: Should any part of this method statement require

amendment or alteration, this must be notified for agreement by all relevant parties prior to it

being enforced.

Communicate method statement: Communicate to all relevant parties (via toolbox talk) and

ensure it is signed by all personnel.

This method statement was prepared by: J. Surebrick.

Date: 19/01/11.

(Note - this method statement has been developed using the site specific risk assessment, the

designer’s residual risk register, ‘Health and safety in excavations - Be safe and shore’ (HSG185),

‘Avoiding danger from underground services’ (HSG 47), ‘Avoidance of danger from overhead

power lines’ (guidance note GS 6) and ‘Safe work in confined spaces’ (L010).)

A P R A C T I C A L G U I D E F O R T H E S M A L L E R C O N T R A C T O R

Method statement record:

Please sign to confirm you have read and understand this method statement.

Name: Company: Signature: Date:

A. DiGGer Sure Foundations Ltd 20/01/11

b. bAnkSMAn Sure Foundations Ltd 20/01/11

c. DuMPer Sure Foundations Ltd 20/01/11

D. SLinGer Sure Foundations Ltd 20/01/11